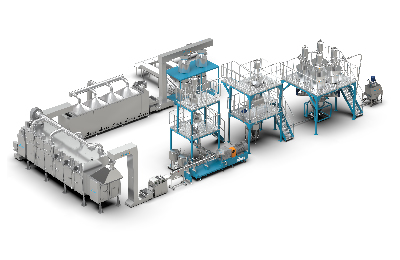

Solution Introduction

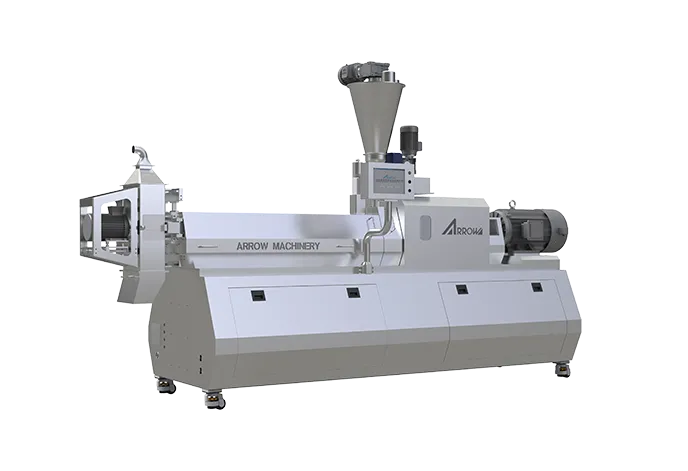

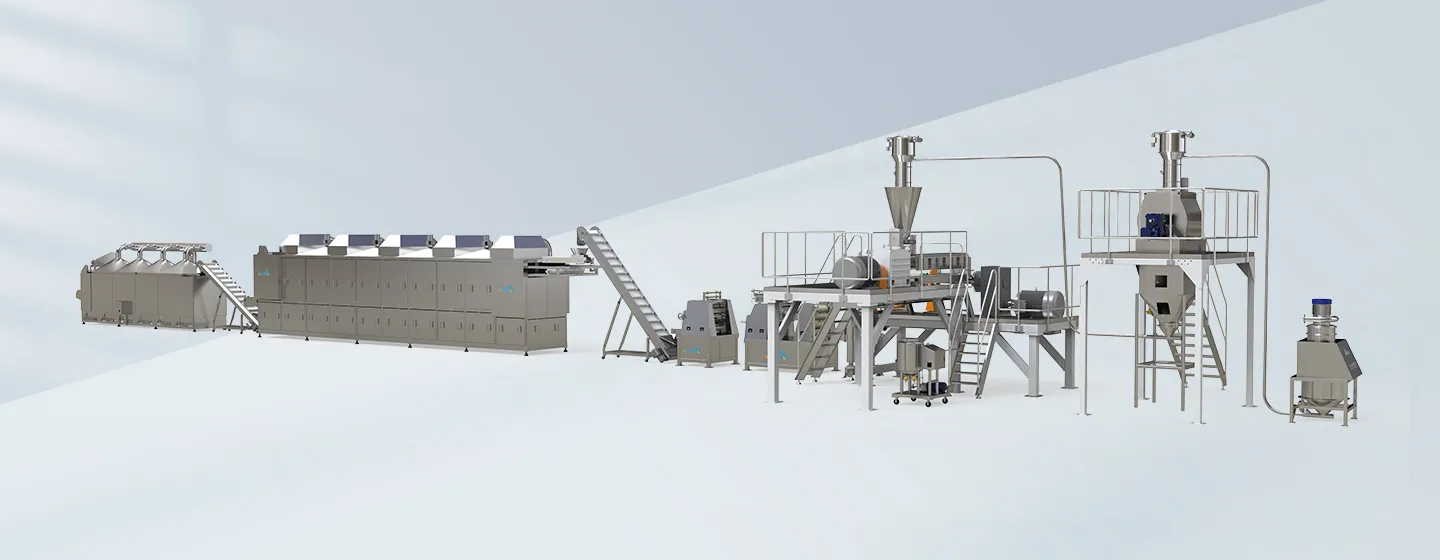

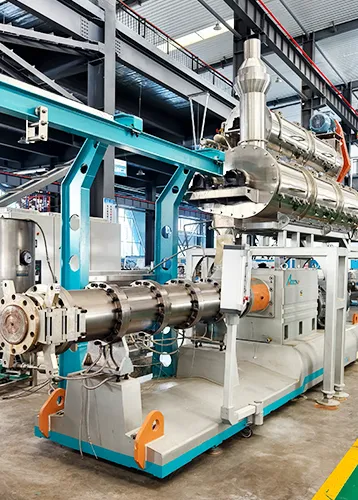

Snack foods are a classic and beloved product, made using twin-screw extruders. Corn, wheat, and rice starch are fed into the extruder barrel, where they undergo shearing and release at higher temperatures and pressures, expanding in the delivery zone. The final product shape can be customized by adjusting the die nozzle.

Zhennuo offers solutions for extruded snacks. By combining various equipment, we can produce flavorful snacks such as straight-cut snacks, chocolate-filled snacks, Doritos, potato chips, fried snacks, and corn sticks. These delicious, diverse, and easy-to-digest snacks are highly popular with consumers.

。

Finished Product Display

Production Process

Grain Powder

-

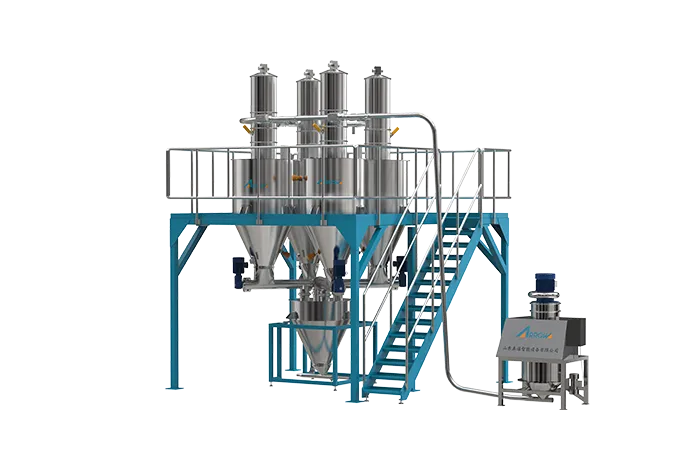

Batching

01

Batching

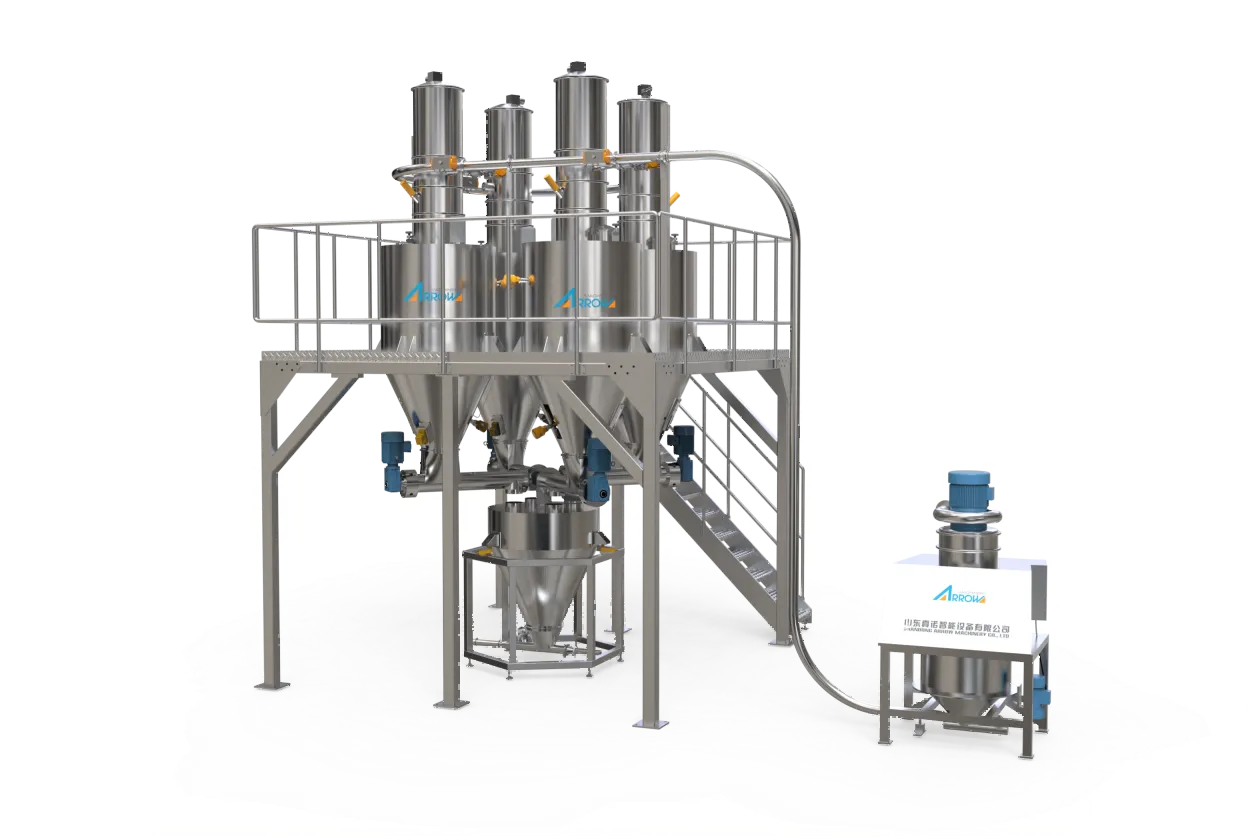

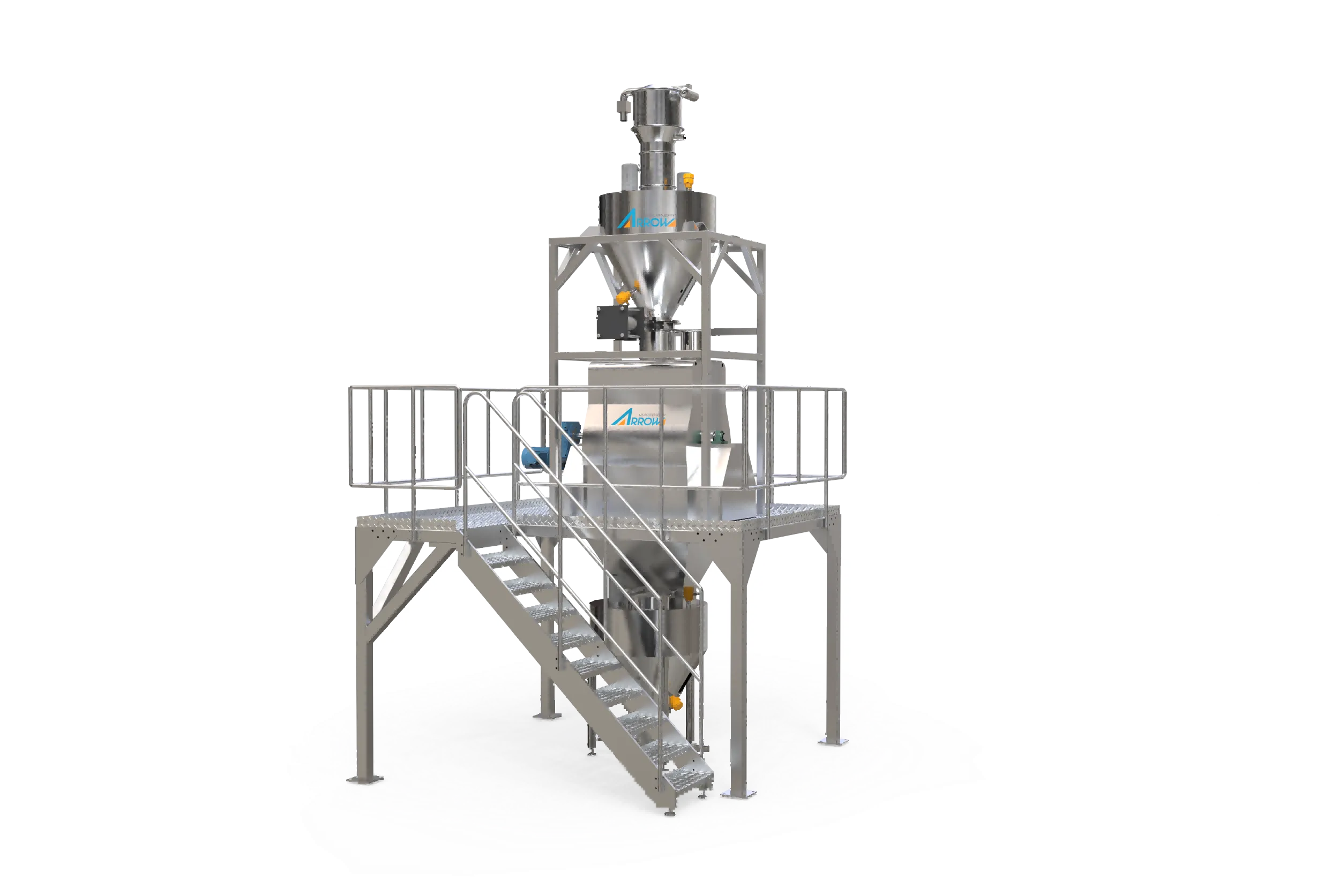

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02Learn MoreThe double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

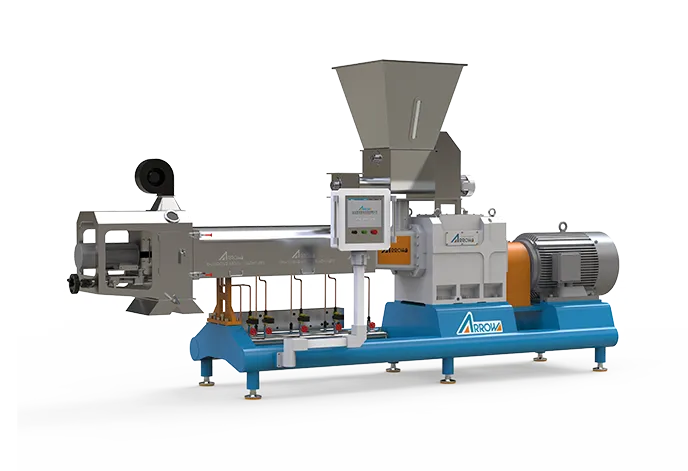

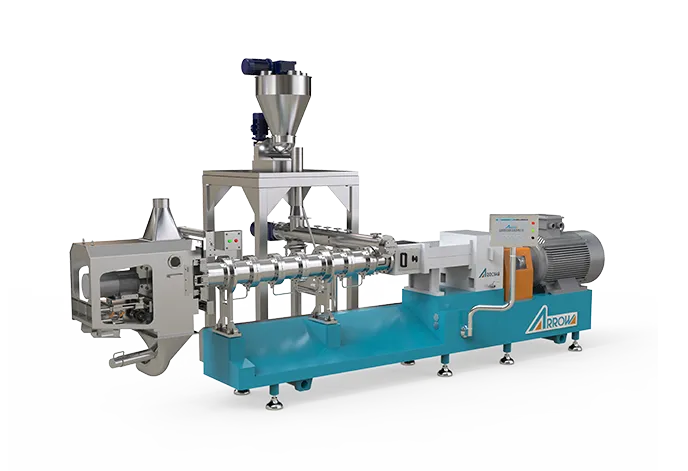

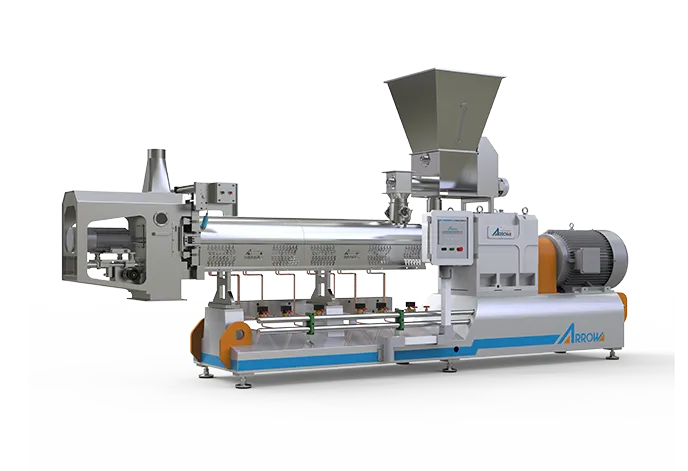

Extrusion

03

Extrusion

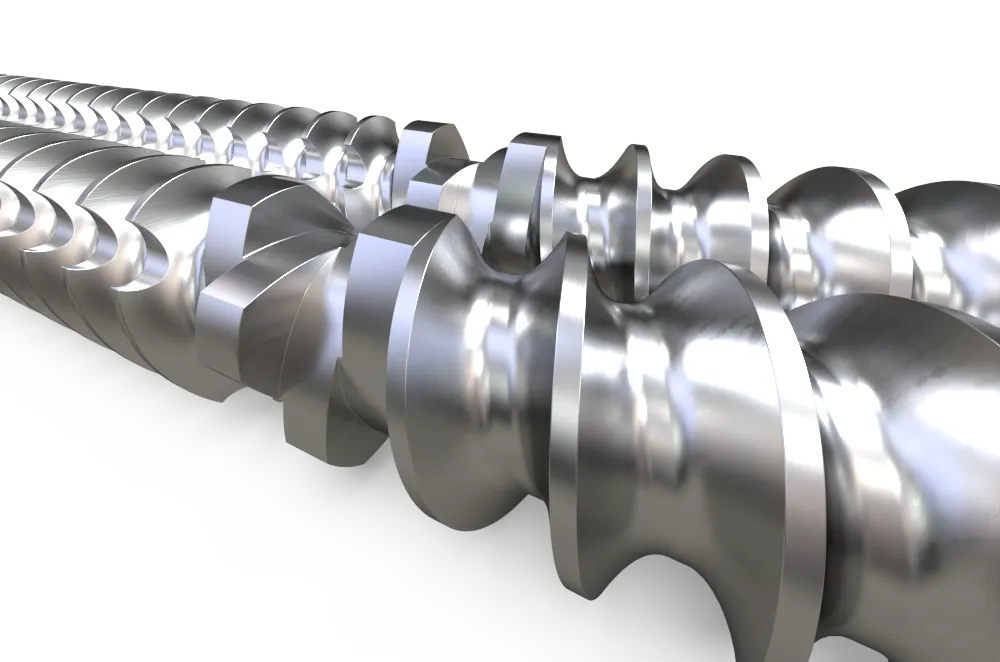

03Through the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

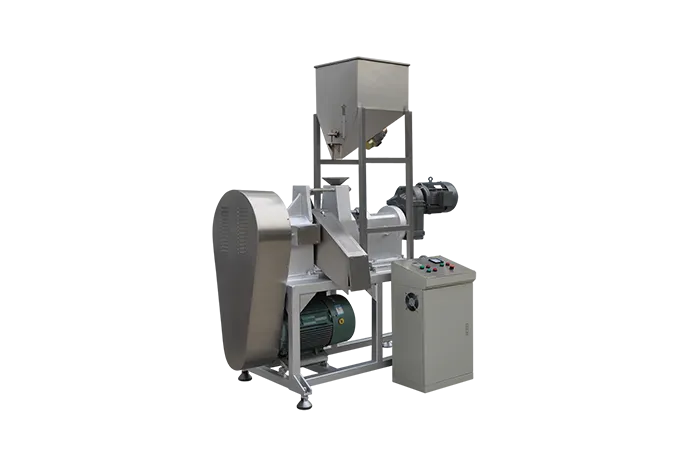

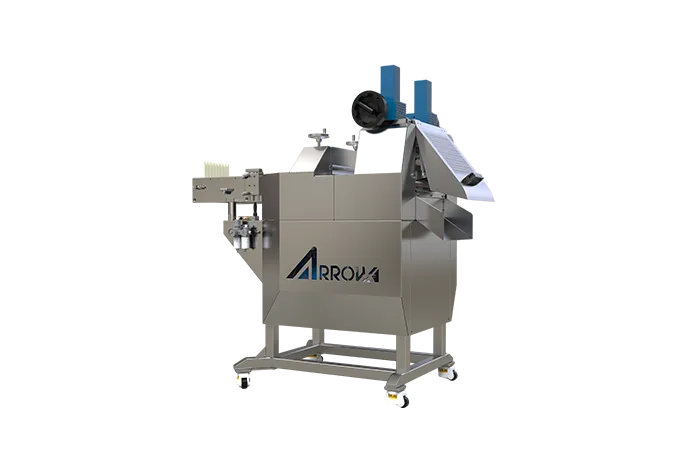

Forming

04

Forming

04By changing the mold, forming machine and cutting machine to change the shape of the product, the raw materials are accurately converted into products of the required shape.

-

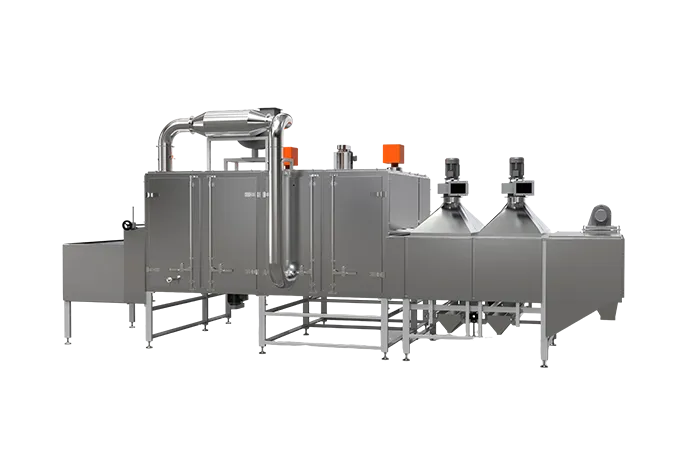

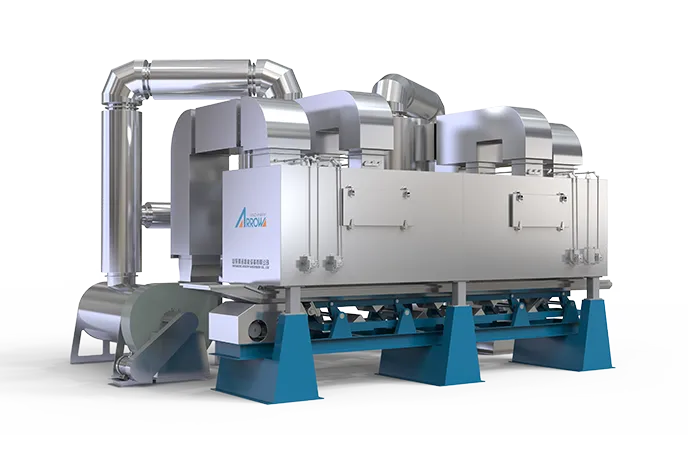

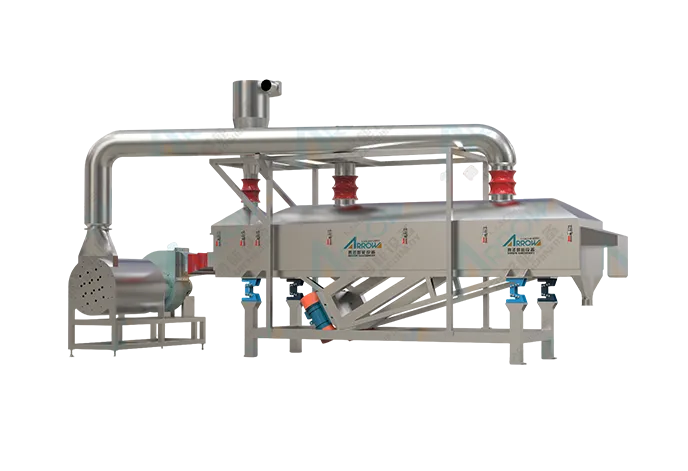

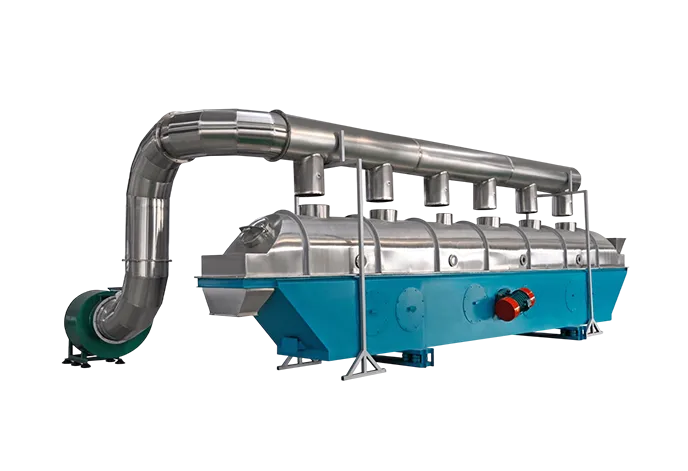

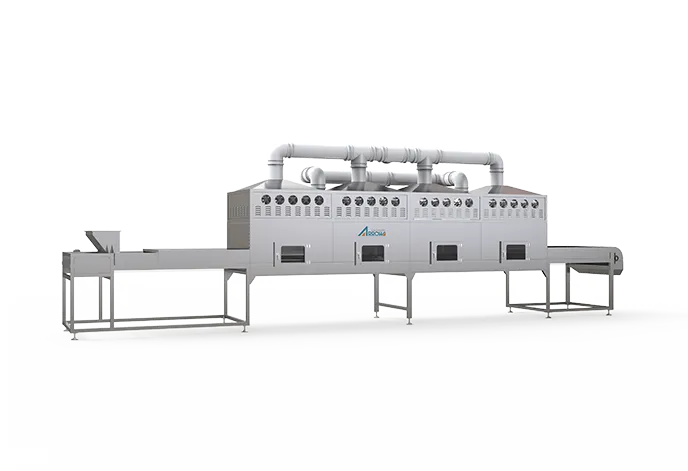

Drying

05

Drying

05The dryer features a forced hot air circulation system to improve thermal processing efficiency. The heat source can be a variety of heat media, including electricity, natural gas, fuel oil, and steam. The control system uses a PLC module for more precise temperature control.

-

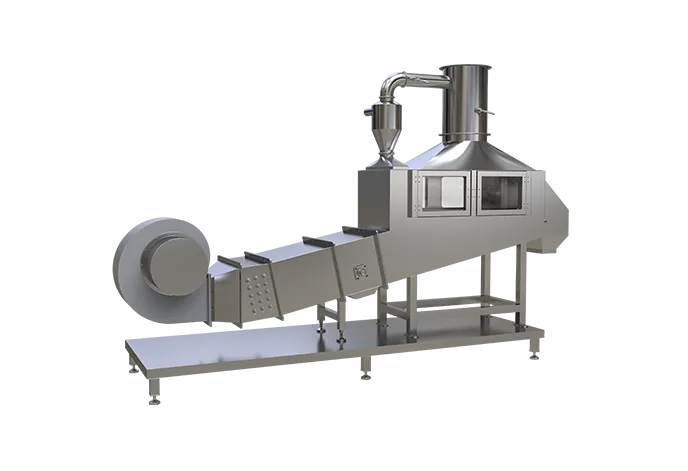

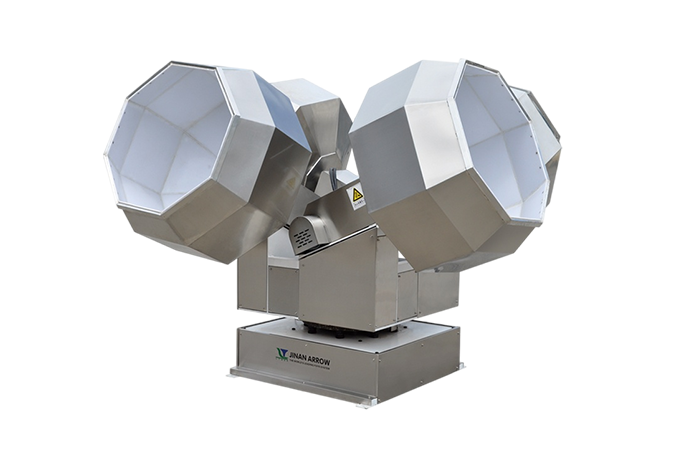

Coating

06

Coating

06Increase the flavor and taste diversity of the product to make it more in line with the taste needs of consumers. At the same time, the coating can also improve the shelf life and stability of the product to a certain extent.

Filled Puffed Snacks

Grain Powder

-

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02The double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

Extrusion

03

Extrusion

03Through the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

Forming

04

Forming

04By changing the mold, forming machine and cutting machine to change the shape of the product, the raw materials are accurately converted into products of the required shape.

-

Frying

05

Frying

05Removing moisture, shaping three-dimensional shapes, enhancing flavor and taste, and possessing antibacterial function, ensuring that the product is crispy, delicious, safe, and hygienic.

-

Coating

06

Coating

06Increase the flavor and taste diversity of the product to make it more in line with the taste needs of consumers. At the same time, the coating can also improve the shelf life and stability of the product to a certain extent.

Crispy Chips/Bugles/Sticks

玉米糁

-

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02The double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

Extrusion

03

Extrusion

03Through the rotation and extrusion of the extruder screw, the raw materials undergo shearing, mixing, and maturation processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

Separation

04

Separation

04Effectively separate finished products from waste materials to ensure that only qualified products enter the next process.

-

Frying

05

Frying

05It removes moisture, shapes the product into a three-dimensional shape, enhances the flavor and taste, and also has a sterilization function, thus ensuring that the product is crispy, delicious, safe and hygienic.

-

Coating

06

Coating

06Increase the flavor and taste diversity of the product to make it more in line with the taste needs of consumers. At the same time, the coating can also improve the shelf life and stability of the product to a certain extent.

奇多栗米条

营养米

-

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02The double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

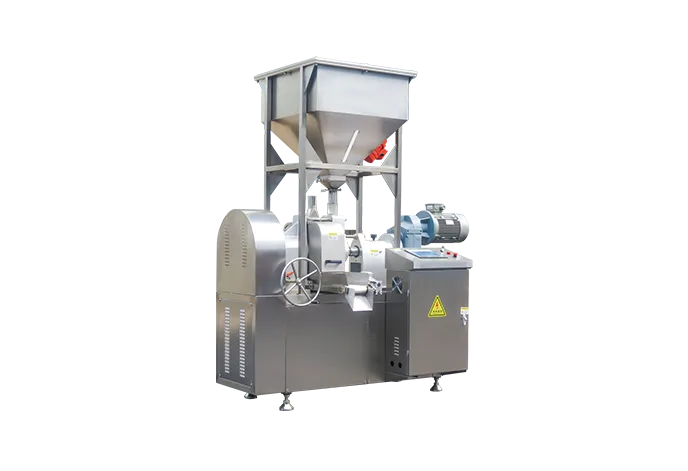

Puffing

03

Puffing

03The raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

Drying

04

Drying

04The dryer features a forced hot air circulation system to improve thermal processing efficiency. The heat source can be a variety of heat media, including electricity, natural gas, fuel oil, and steam. The control system uses a PLC module for more precise temperature control.

-

Coating

05

Coating

05Increase the flavor and taste diversity of the product to make it more in line with the taste needs of consumers. At the same time, the coating can also improve the shelf life and stability of the product to a certain extent.

爆米饼

谷物粉

-

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02The double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

Extrusion

03

Extrusion

03Through the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

Forming

04

Forming

04By changing the mold, forming machine and cutting machine to change the shape of the product, the raw materials are accurately converted into products of the required shape.

-

Frying

05

Frying

05It removes moisture, shapes the product into a three-dimensional shape, enhances the flavor and taste, and also has a sterilization function, thus ensuring that the product is crispy, delicious, safe and hygienic.

-

Coating

06

Coating

06Increase the flavor and taste diversity of the product to make it more in line with the taste needs of consumers. At the same time, the coating can also improve the shelf life and stability of the product to a certain extent.

膨化油炸食品

Customer Cases

Our Industry Advantages

-

Over 30 Years Of Industry Experience

We have over 30 years of experience in the manufacturing of extruded foods and are familiar with global development trends. Through close cooperation with you, we provide you with a one-stop solution that suits you, including full process design, workshop layout design, and workshop construction guidance.

-

Leading The Production Frontier

We specialize in creating intelligent, efficient, long-lasting, and energy-efficient fully automated production solutions, ensuring stable system operation and leading the industry's technological forefront. Every process adheres to strict food safety standards to safeguard your production.

-

Product Innovation

Our team of food technologists and engineers work closely together to keep pace with market trends and understand evolving tastes. We continuously innovate equipment and formulations to create tailored extruded food solutions that meet future market demands and help us pioneer new trends in the industry.

-

Global Quality Service

Our machinery and engineering services are available in over 110 countries and regions. Regardless of your location, you can expect responsive, attentive service. Our dedicated team is always on hand to resolve production issues, optimize your facility performance, and ensure a smooth and worry-free production journey.

Comprehensive Customized Engineering Solutions

Service Process

-

01

Inquiry

-

02

Design

-

03

Testing

-

04

Plan

-

05

Manufacturing

-

06

Logistics

-

07

Installation

-

08

Debug

-

09

Training

-

10

Turnkey Project

-

11

Service