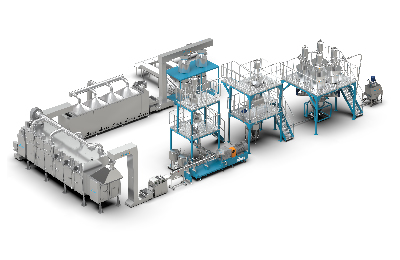

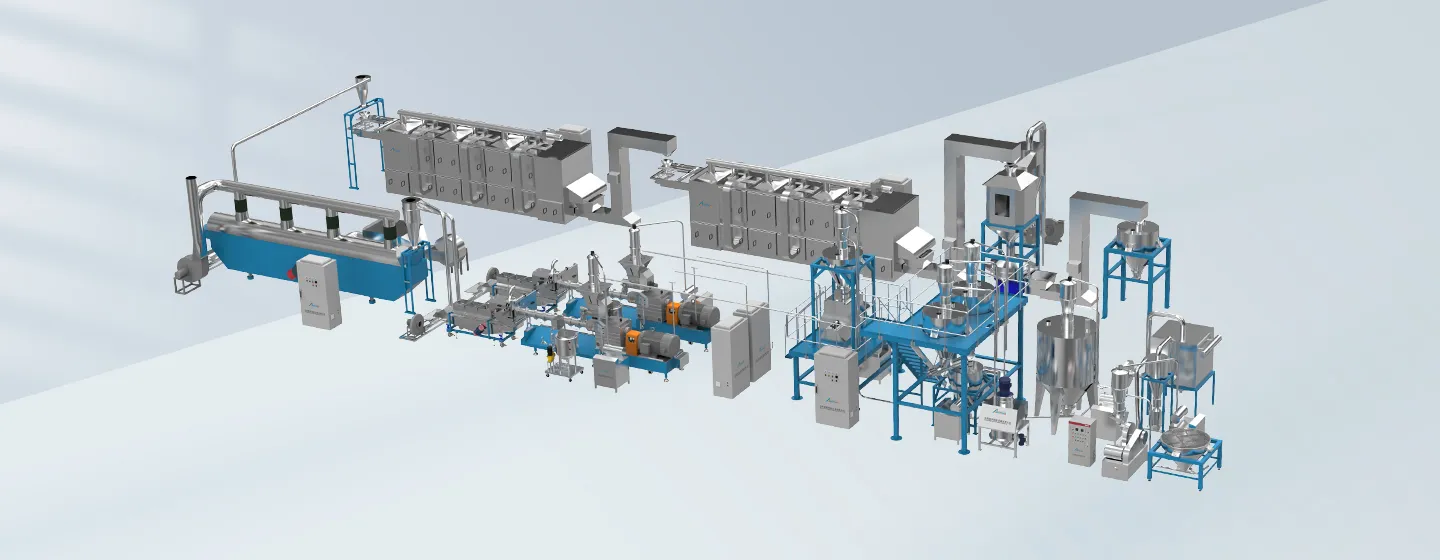

Solution Introduction

Instant rice is made from rice flour with the addition of a variety of grain powders or nutrients. The internal structure of the rice flour is changed using extruder technology. It is then cut into rice grain shapes using a special mold. It is then dried and dehydrated using a fluidized bed dryer, microwave dryer, multi-layer mesh belt dryer, etc. to fix the internal molecular structure of the rice and prevent it from regenerating. It can then be packaged after cooling.

Finished Product Display

Production Process

Grain Powder

-

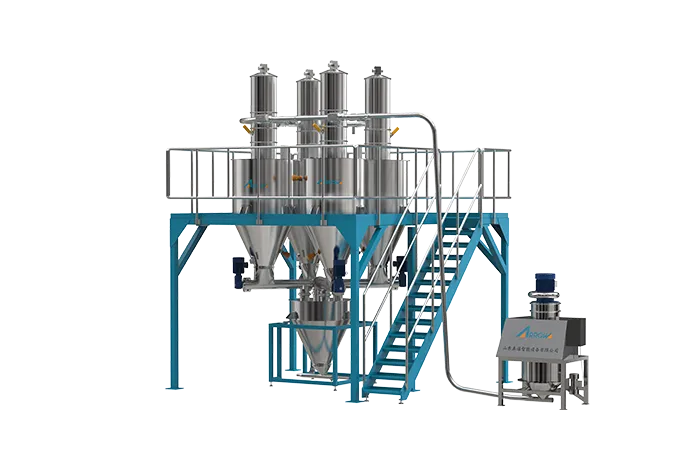

Batching

01

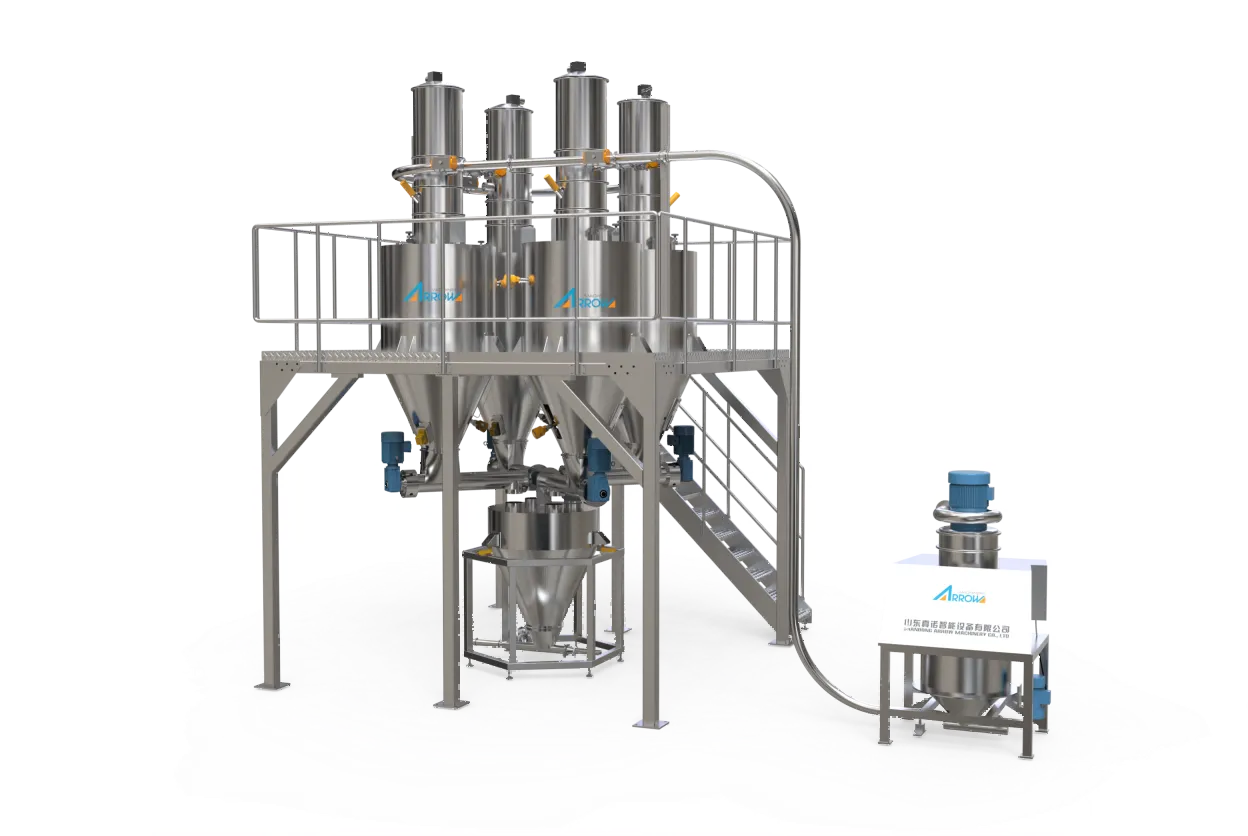

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

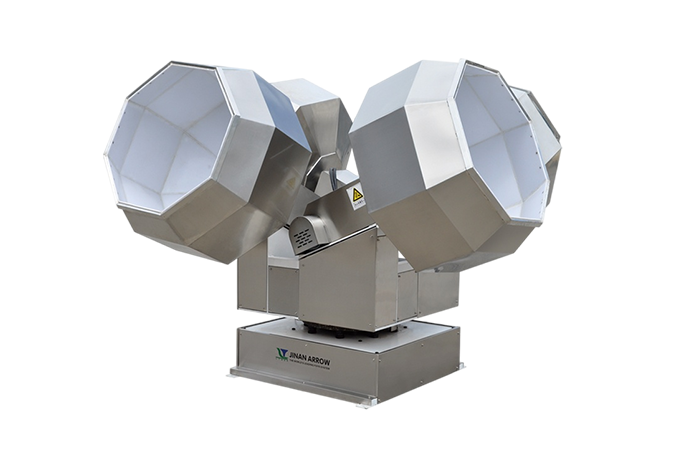

Mixing

02

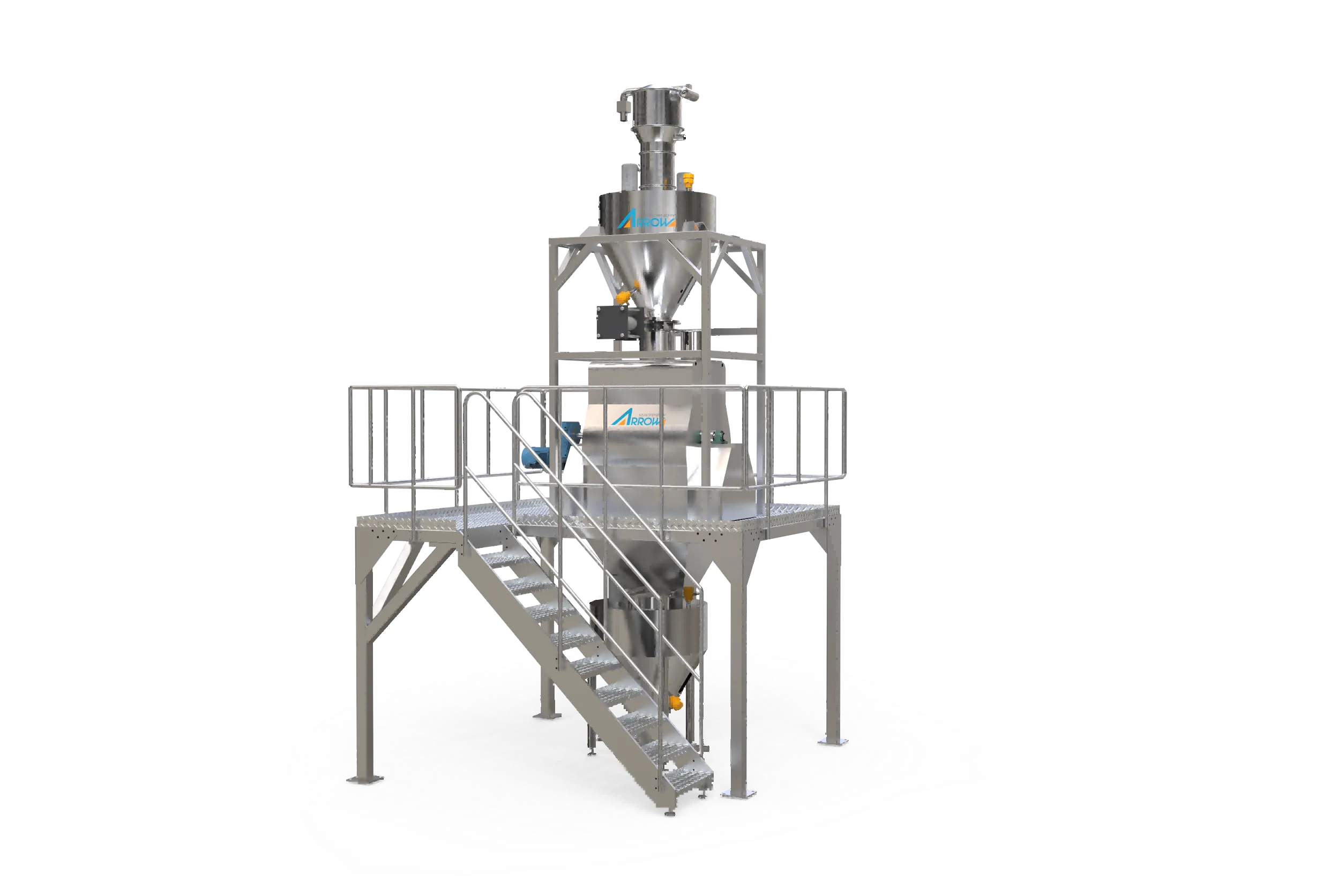

Mixing

02The double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

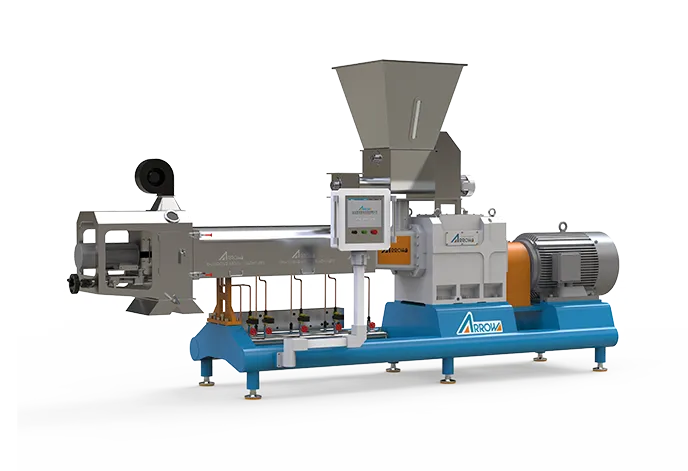

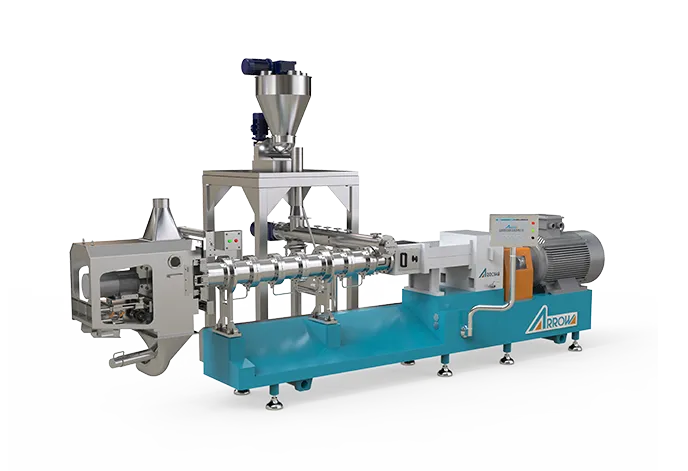

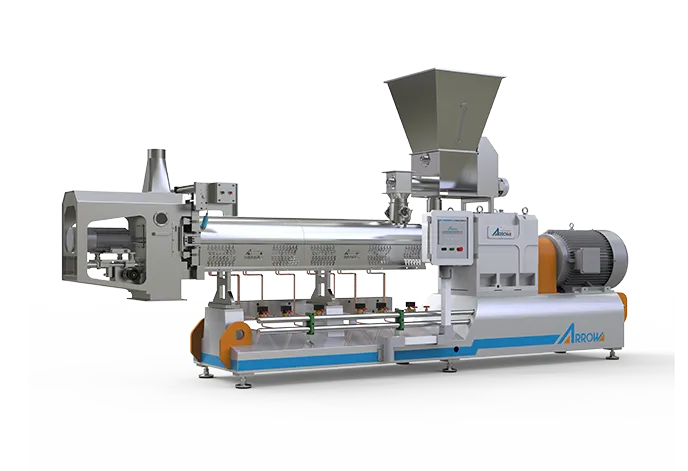

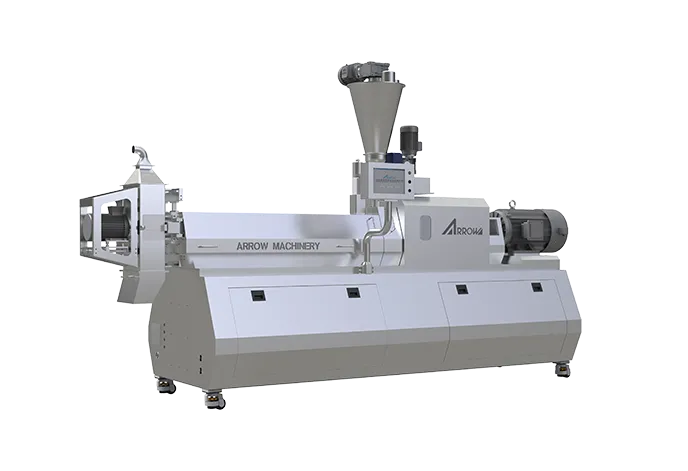

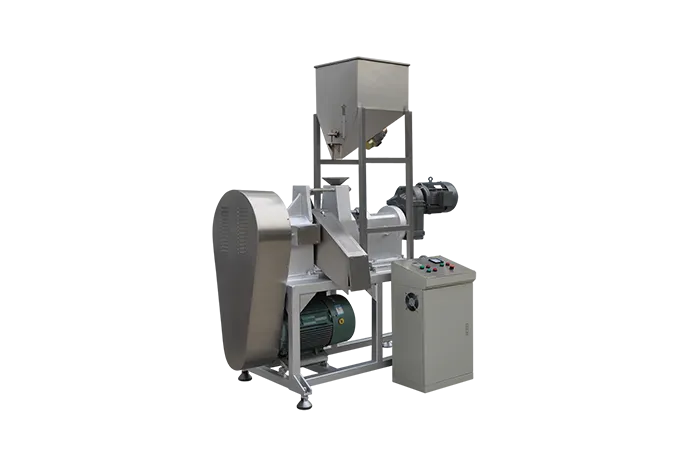

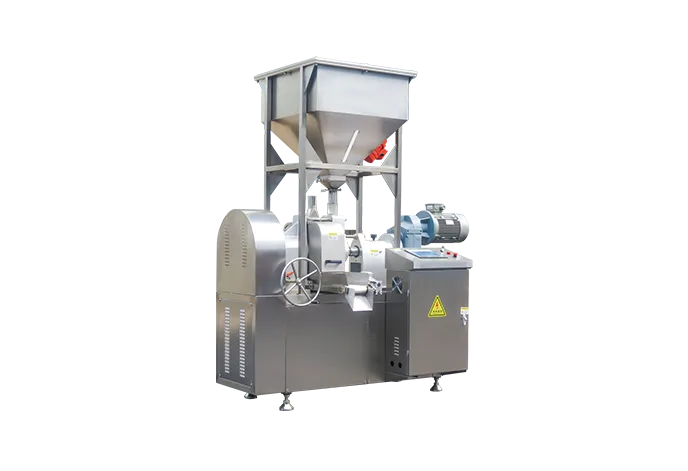

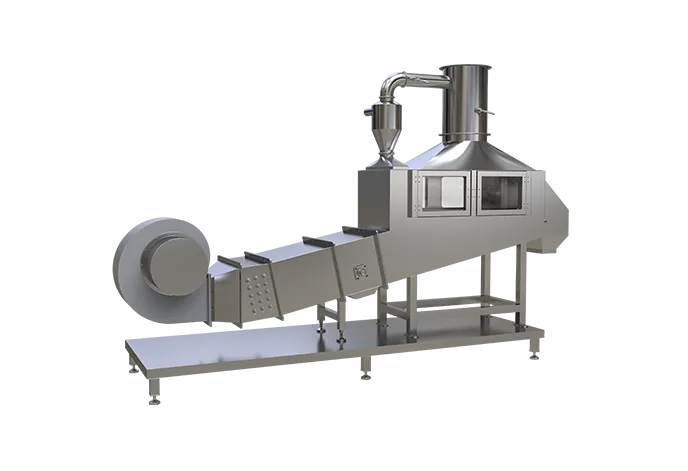

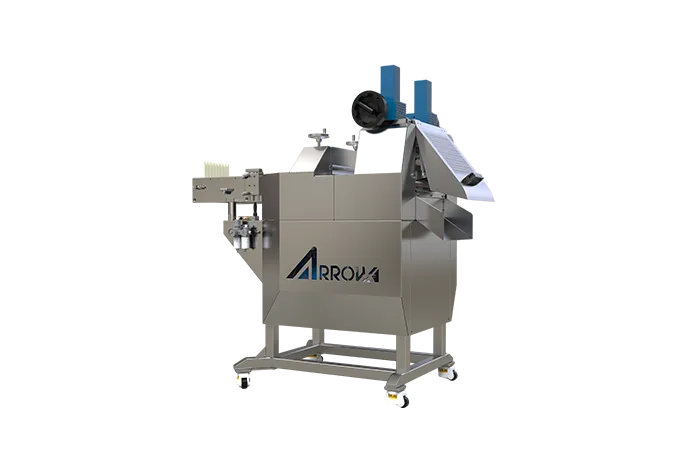

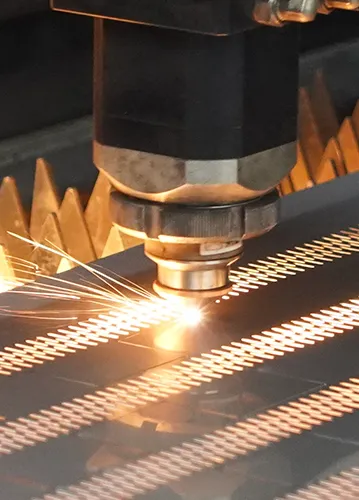

Extrusion

03

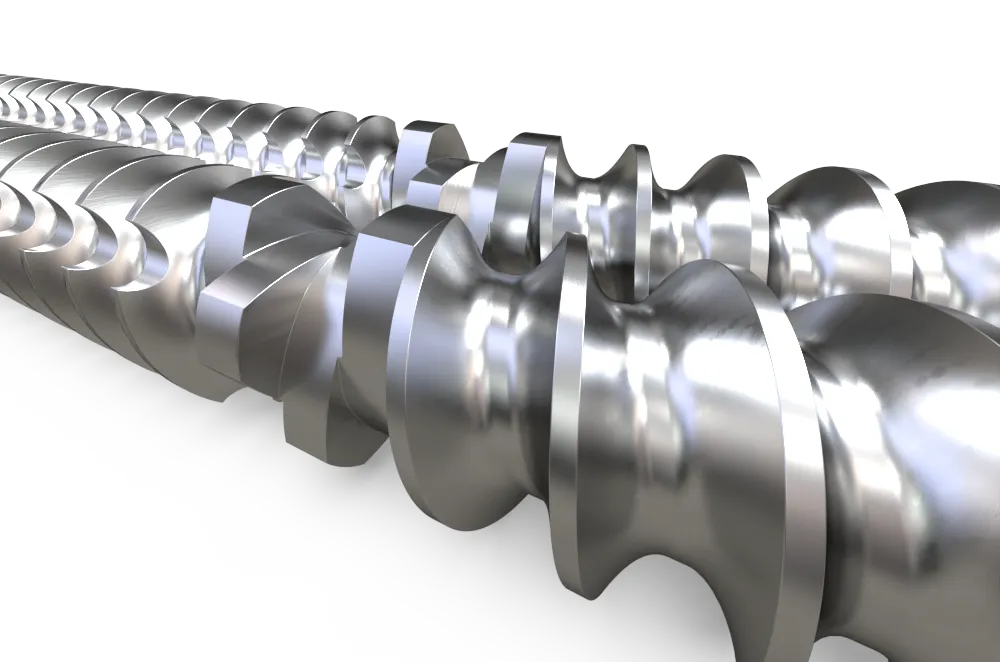

Extrusion

03Learn MoreThrough the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

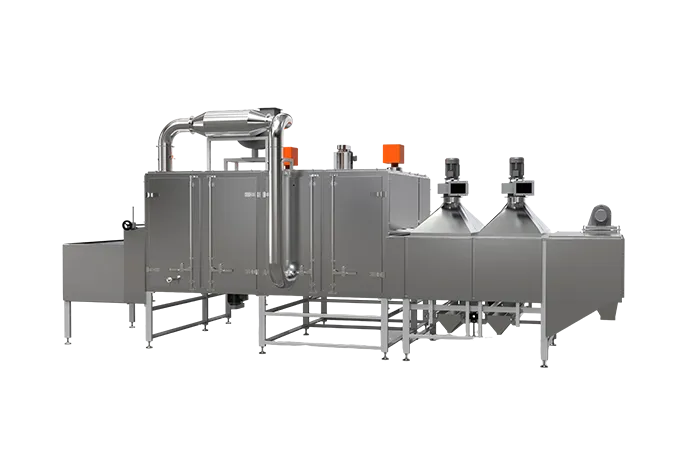

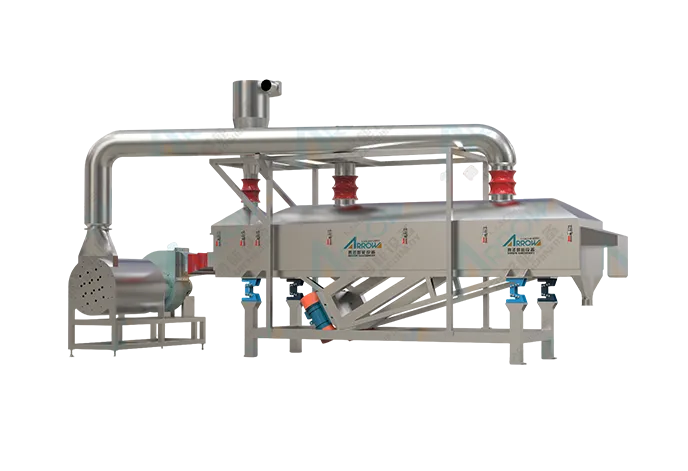

Pre-drying

04

Pre-drying

04Removing some of the moisture from nutritious rice kernels prepares them for the subsequent main drying process and helps maintain the product's shape and taste.

-

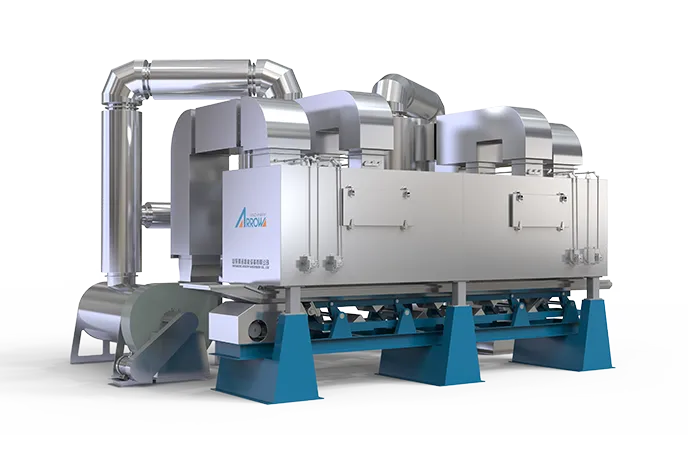

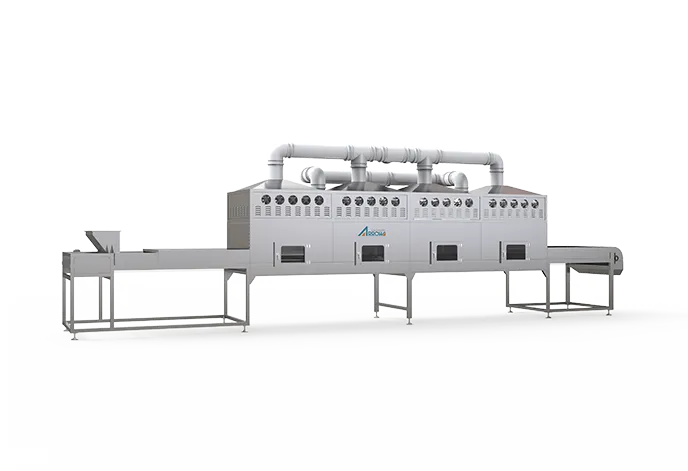

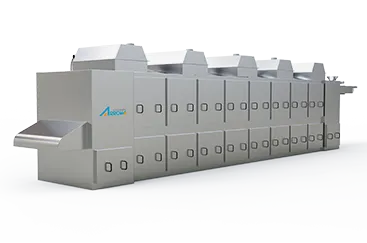

Drying

05

Drying

05Remove the remaining moisture in the nutritious rice grains to meet the requirements of product packaging and storage.

-

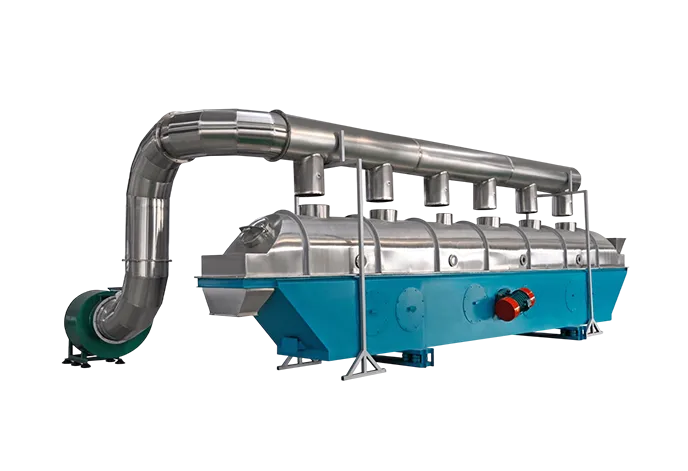

Cooling

06

Cooling

06The product is quickly and evenly cooled and ventilated and dried through cooling equipment to quickly fix its puffed structure and remove excess heat, maintaining the product's crispness and taste and preventing deterioration.

Nutritious Rice

Our Industry Advantages

-

Over 30 Years Of Industry Experience

We have over 30 years of experience in the manufacturing of extruded foods and are familiar with global development trends. Through close cooperation with you, we provide you with a one-stop solution that suits you, including full process design, workshop layout design, and workshop construction guidance.

-

Leading The Production Frontier

We specialize in creating intelligent, efficient, long-lasting, and energy-efficient fully automated production solutions, ensuring stable system operation and leading the industry's technological forefront. Every process adheres to strict food safety standards to safeguard your production.

-

Product Innovation

Our team of food technologists and engineers work closely together to keep pace with market trends and understand evolving tastes. We continuously innovate equipment and formulations to create tailored extruded food solutions that meet future market demands and help us pioneer new trends in the industry.

-

Global Quality Service

Our machinery and engineering services are available in over 110 countries and regions. Regardless of your location, you can expect responsive, attentive service. Our dedicated team is always on hand to resolve production issues, optimize your facility performance, and ensure a smooth and worry-free production journey.

Comprehensive Customized Engineering Solutions

Service Process

-

01

Inquiry

-

02

Design

-

03

Testing

-

04

Plan

-

05

Manufacturing

-

06

Logistics

-

07

Installation

-

08

Debug

-

09

Training

-

10

Turnkey Project

-

11

Service