Solution Introduction

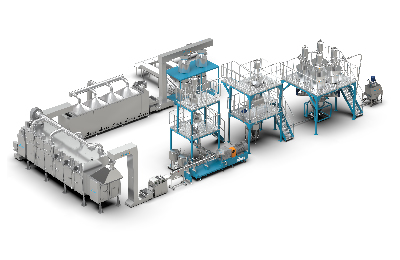

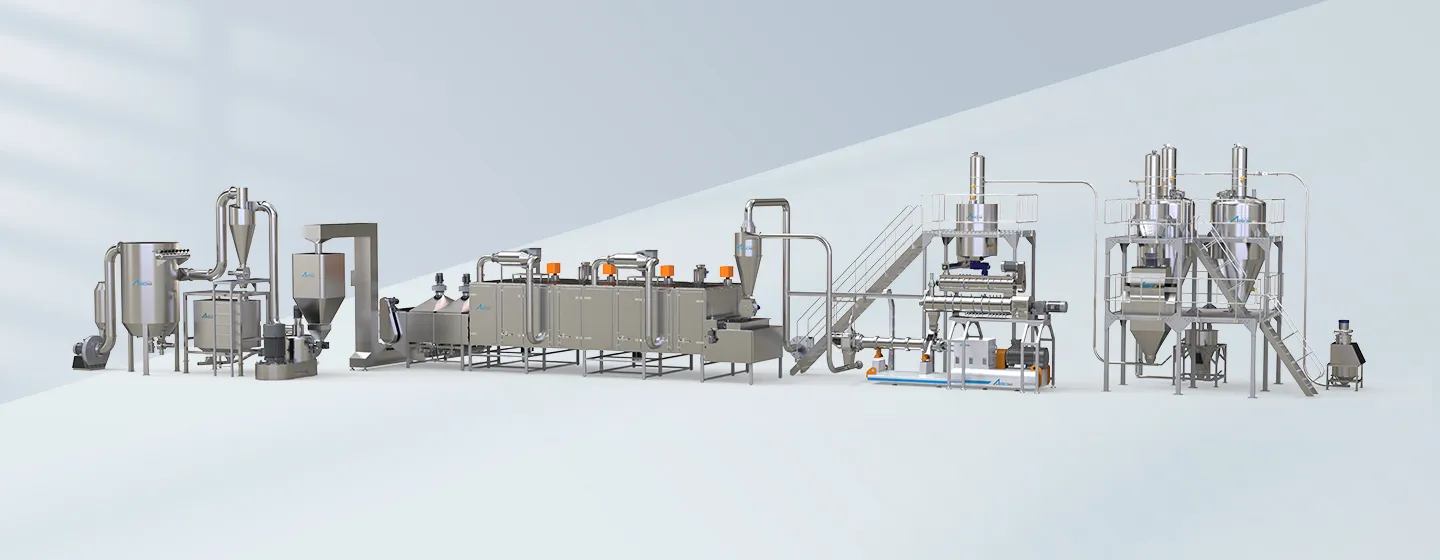

We are committed to using selected grains, fruits, vegetables, and dairy products as raw materials, and carefully crafting a series of nutritionally balanced and easily digestible nutritional powders through advanced production technology and equipment; At the same time, high-tech methods are used to modify starch, producing modified starch with diverse functions and strong adaptability; In addition, we also offer high-quality breadcrumbs, providing the perfect solution for the baking and fast food industries. These three production lines together form a strong lineup for us to provide high-quality raw materials and ingredients for the food industry.

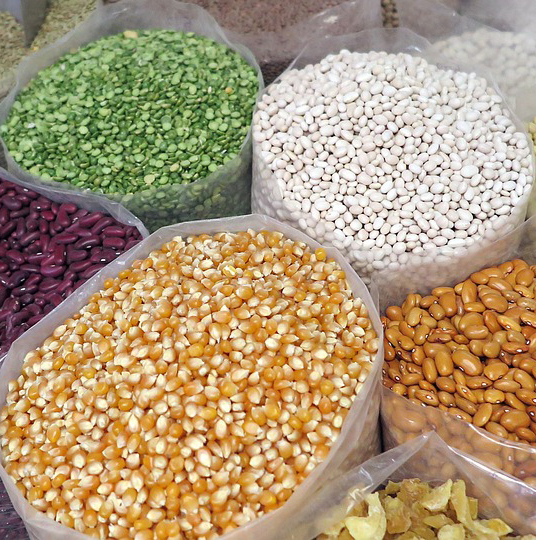

Finished Product Display

Production Process

Grain Powder

-

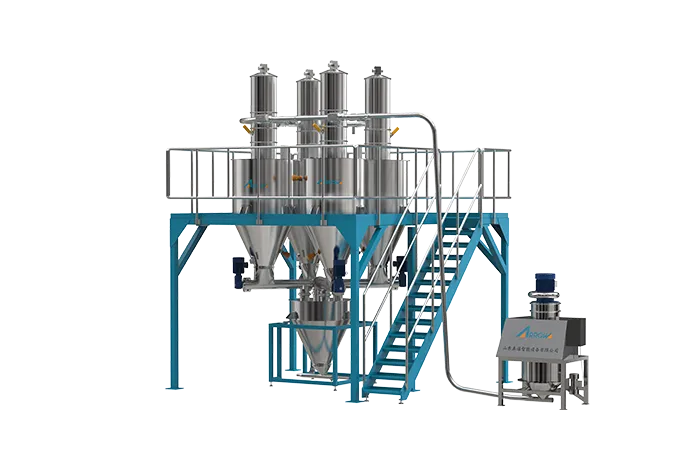

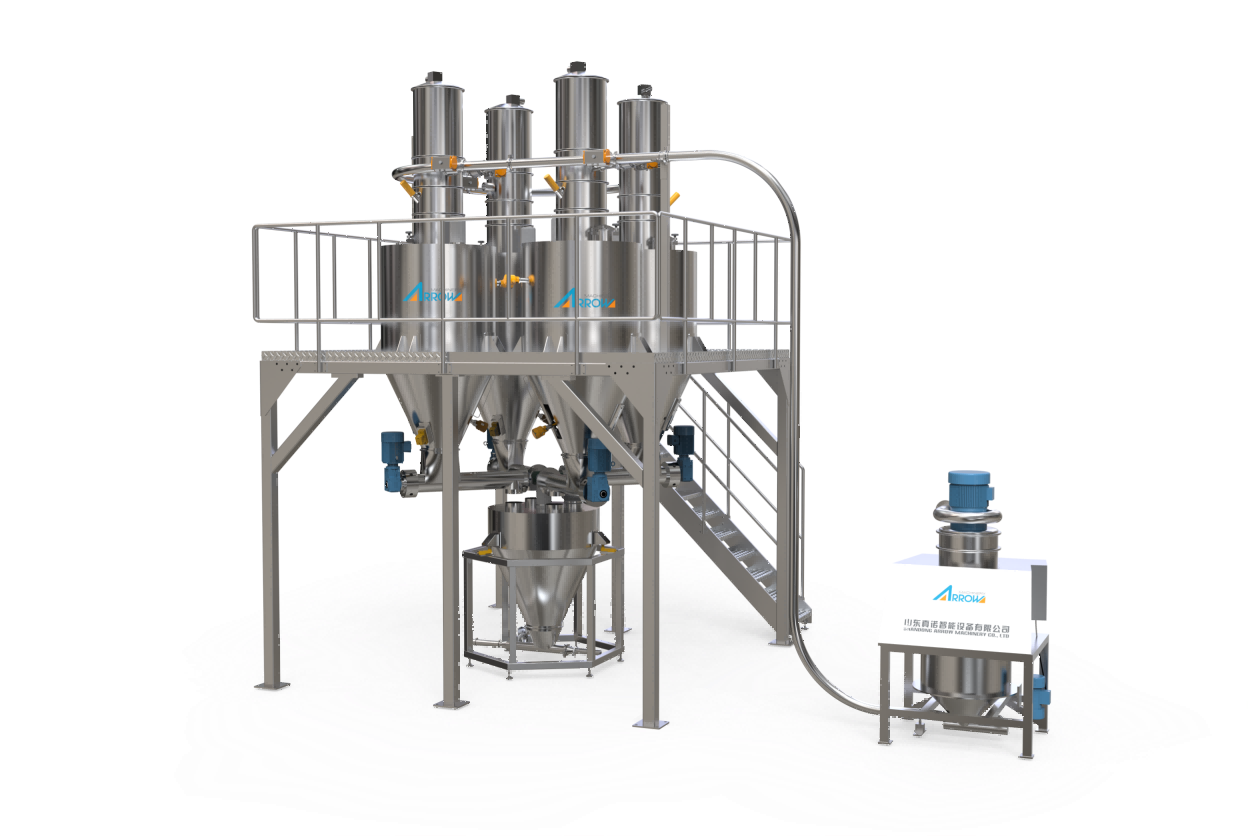

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

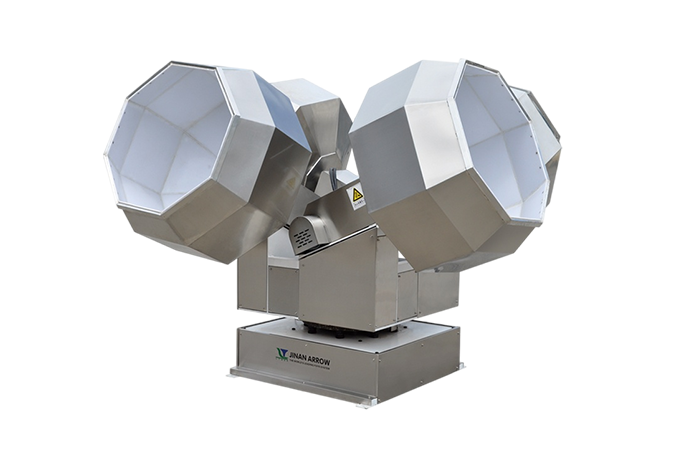

Mixing

02

Mixing

02Adopting a double-layer rotor design, the mixing time is short, the uniformity is high, and the raw materials can be fully mixed. At the same time, a large section return air duct is equipped to reduce dust pollution.

-

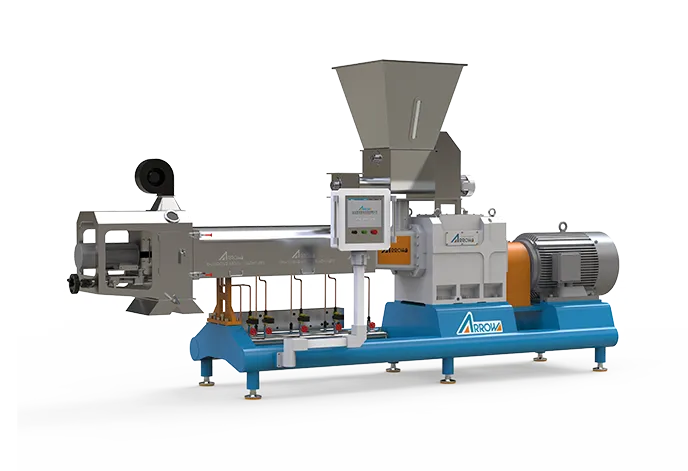

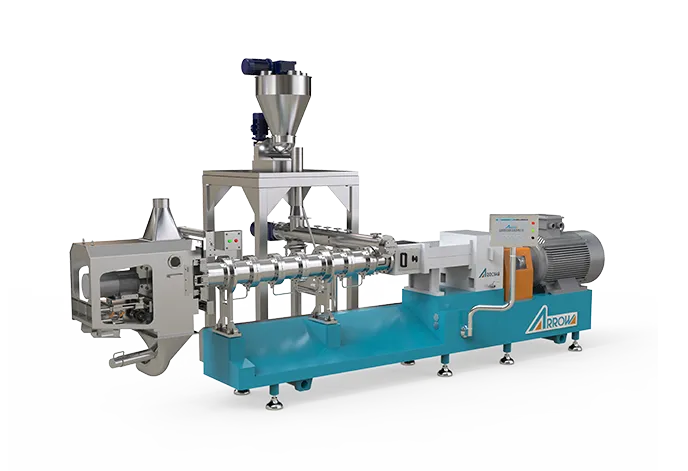

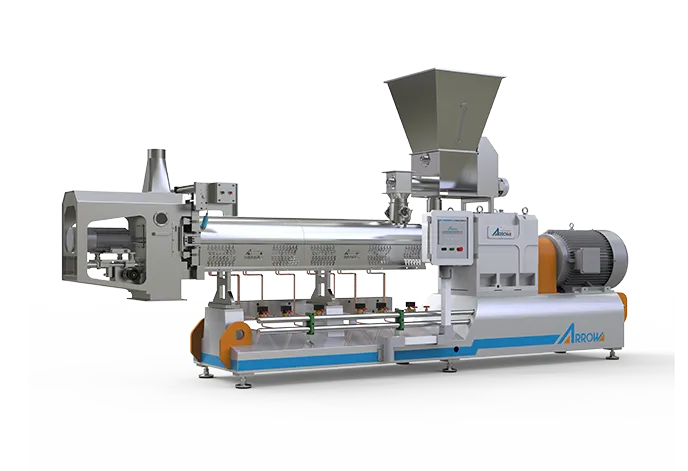

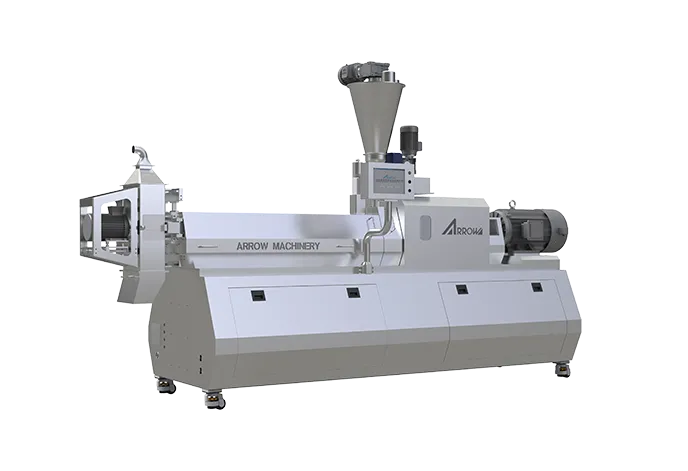

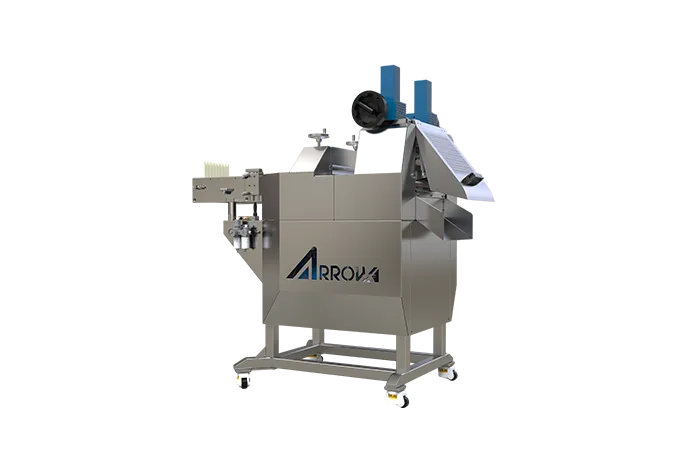

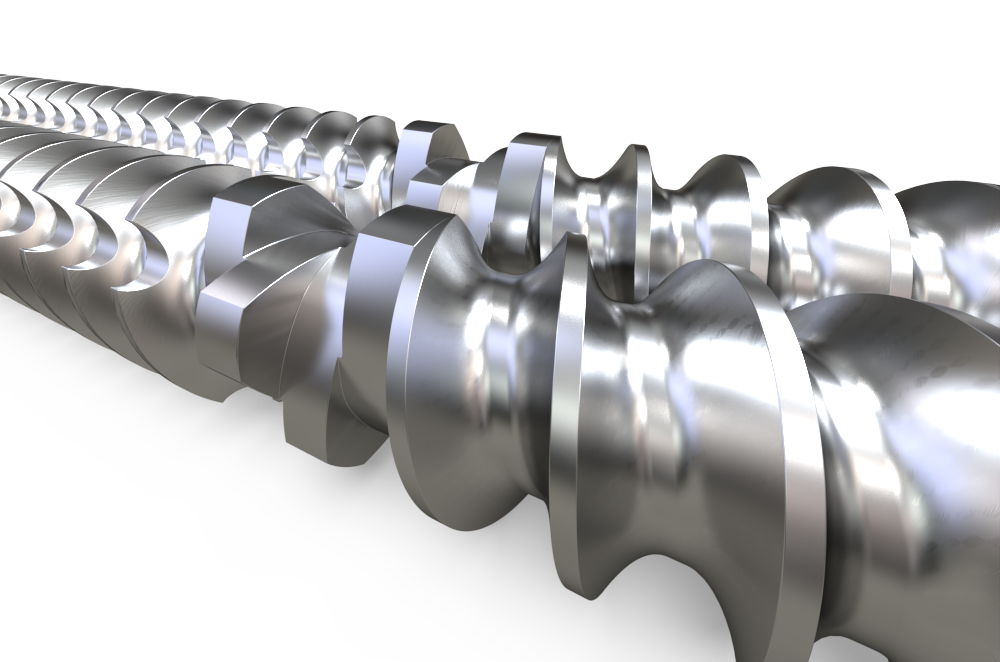

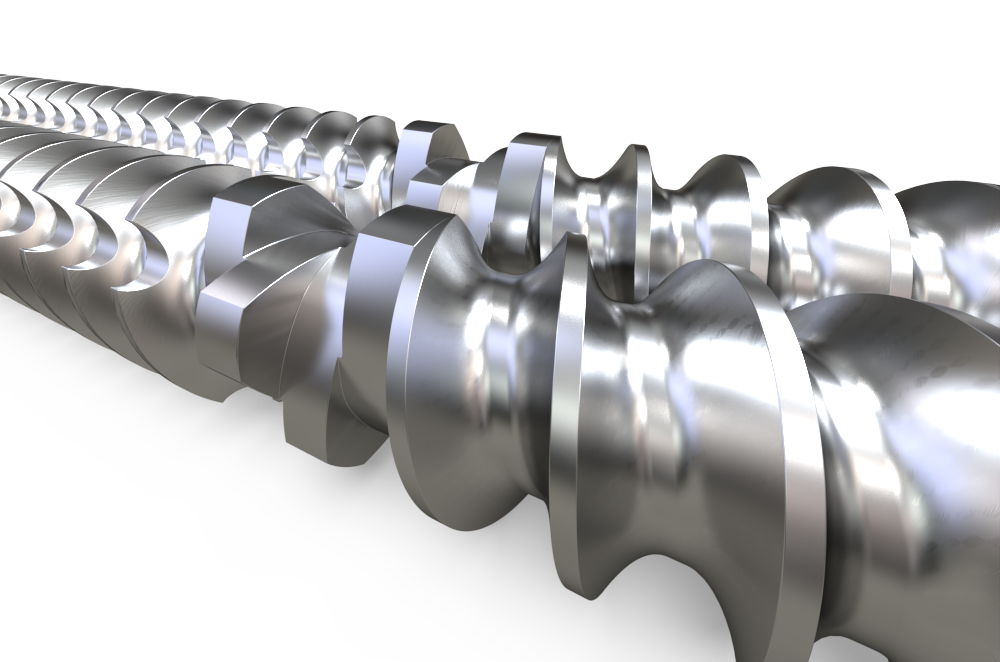

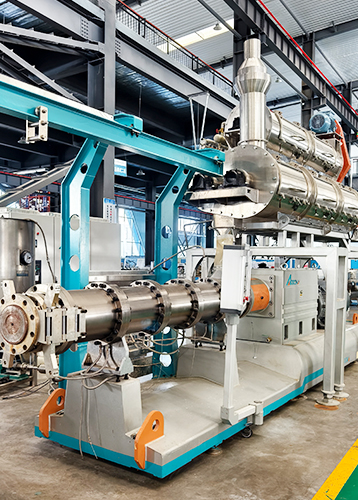

Extrusion

03

Extrusion

03Through the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

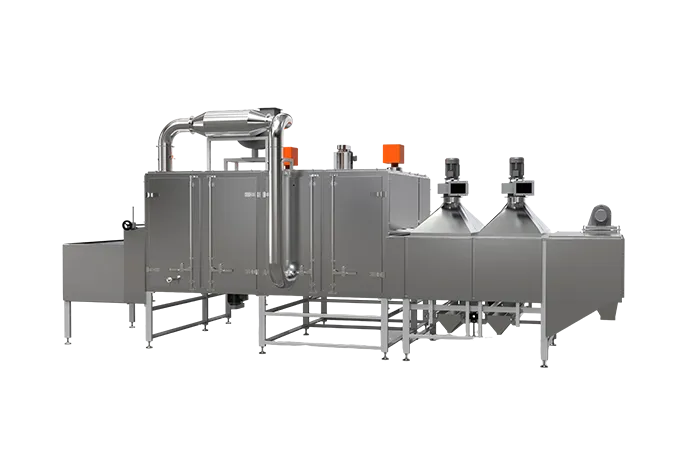

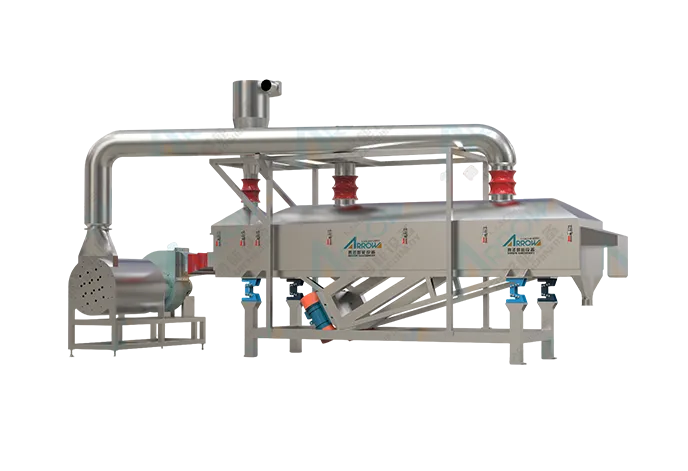

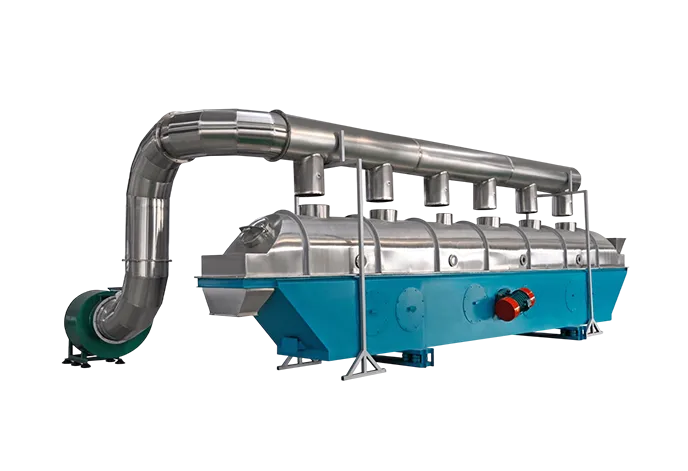

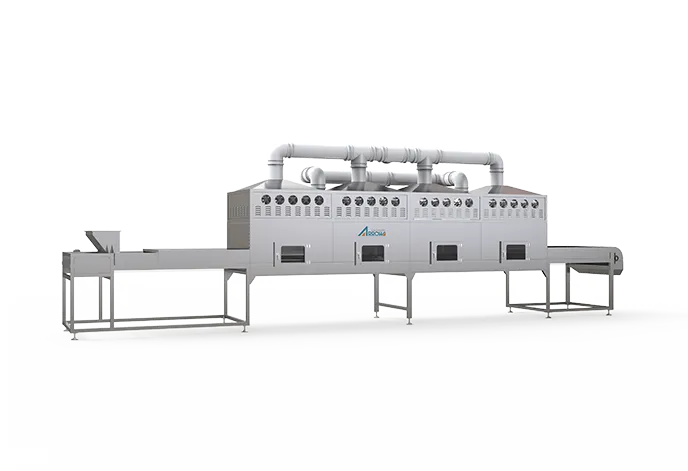

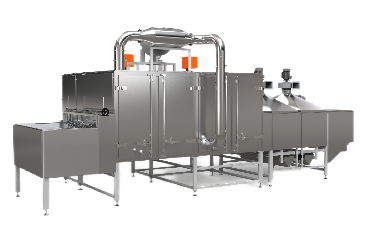

Drying

04

Drying

04The dryer has a forced hot air circulation system to improve the efficiency of thermal processing. The heat source can use various heat media such as electricity, natural gas, fuel oil, steam, etc. The control system adopts PLC module for more precise temperature control.

-

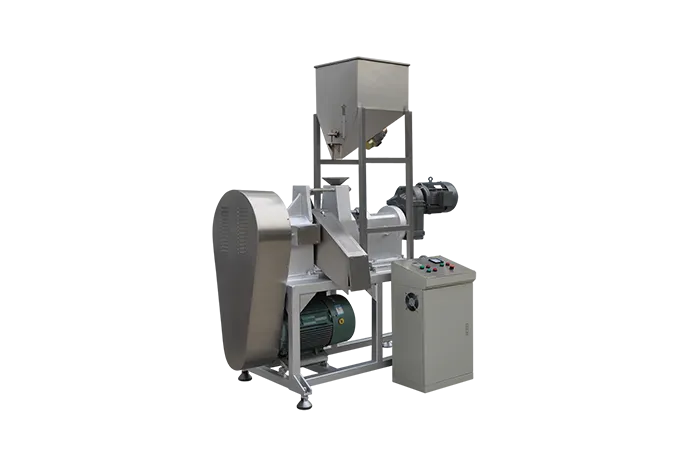

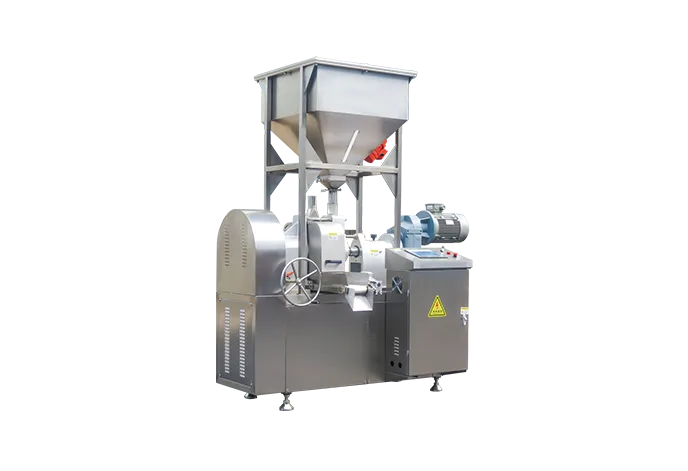

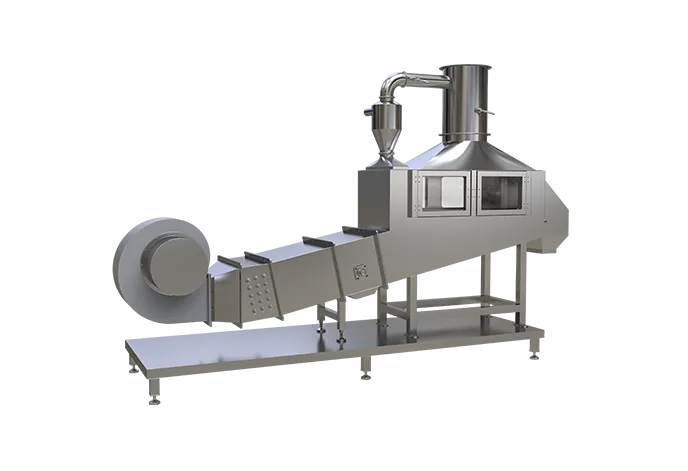

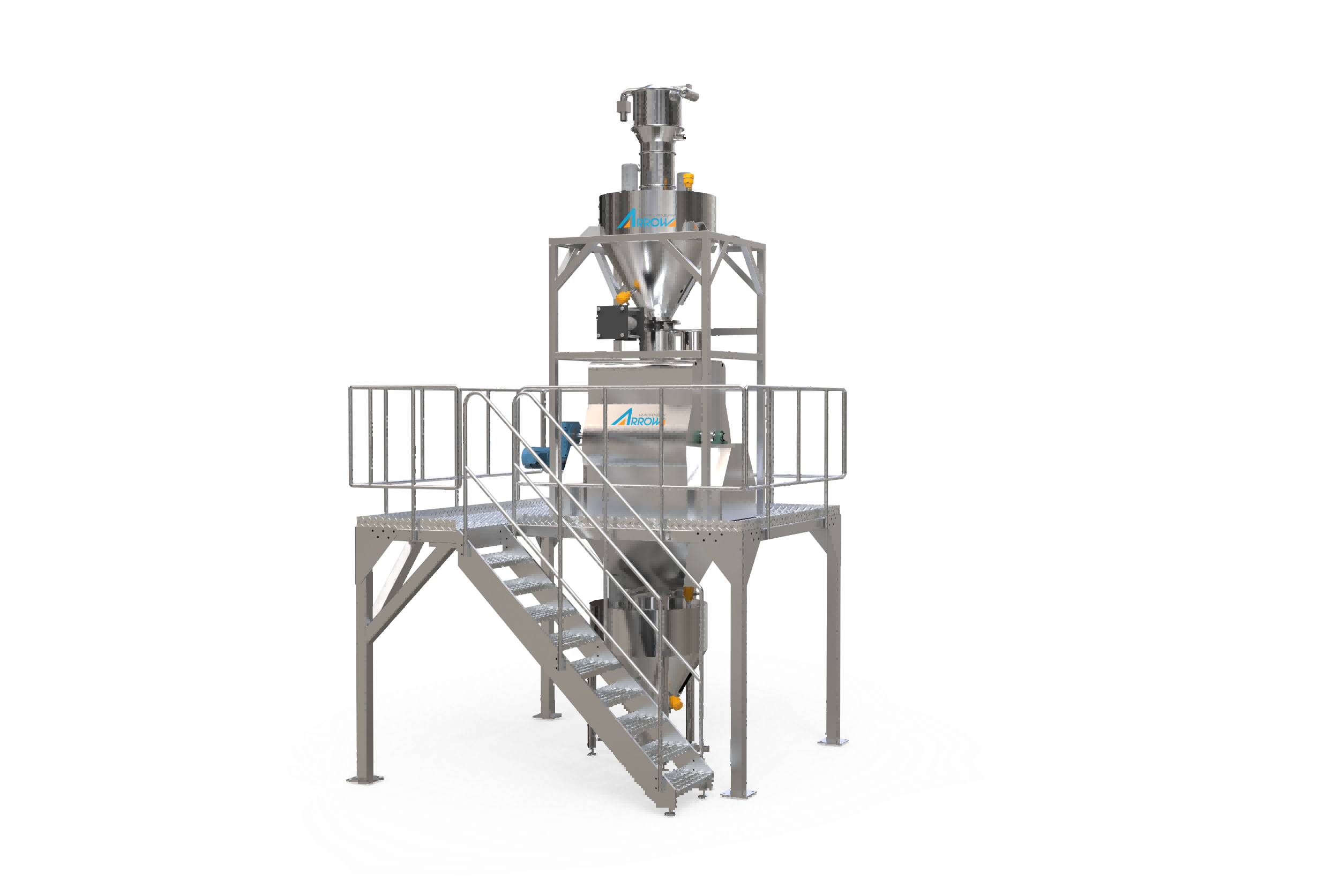

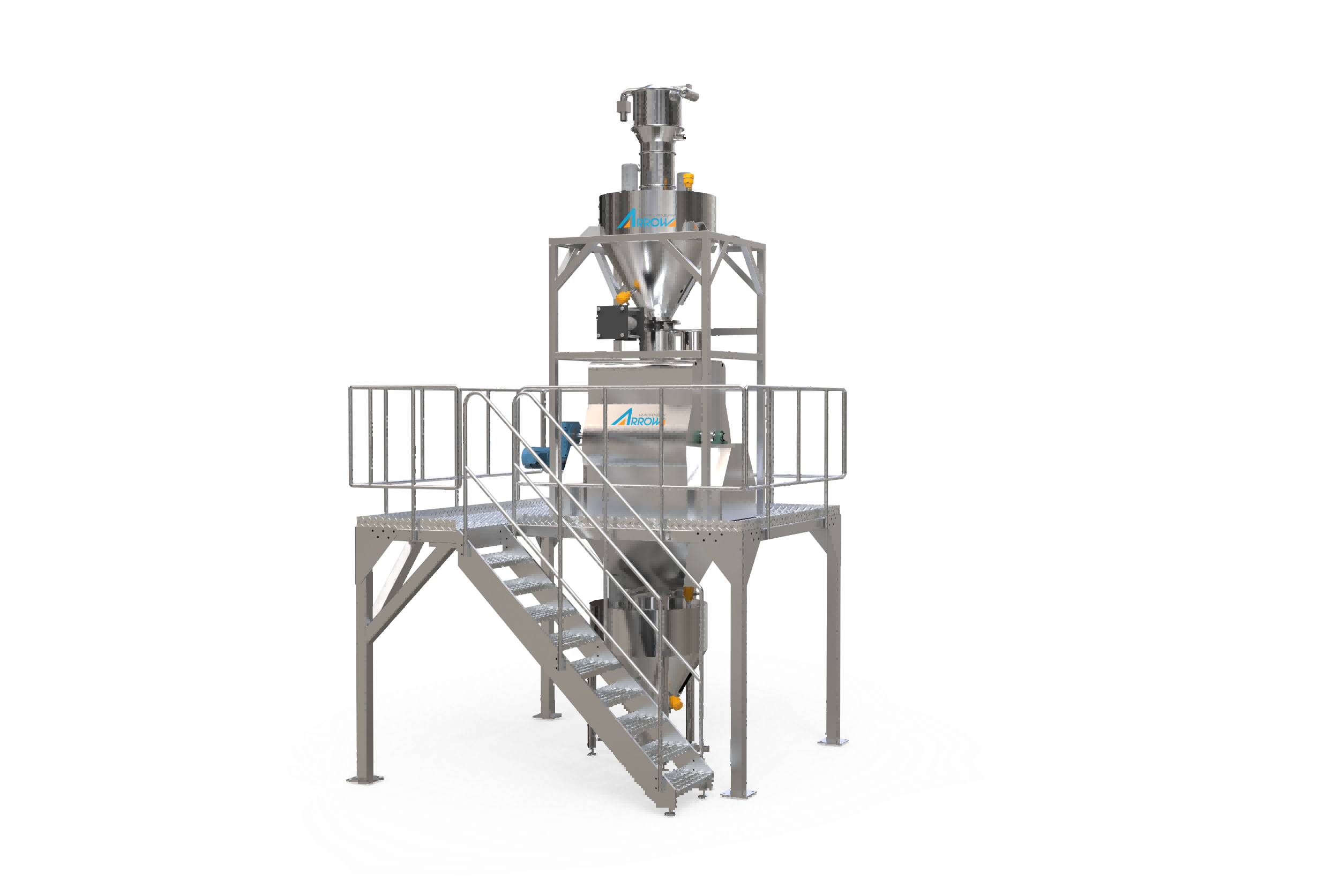

Grinding

05

Grinding

05The product produced by the twin-screw extruder is crushed into powder by a grinder to ensure uniform distribution of nutrients in the powder, thereby improving the overall nutritional value and edible effect of the product.

Nutritional Powder

Grain Starch

-

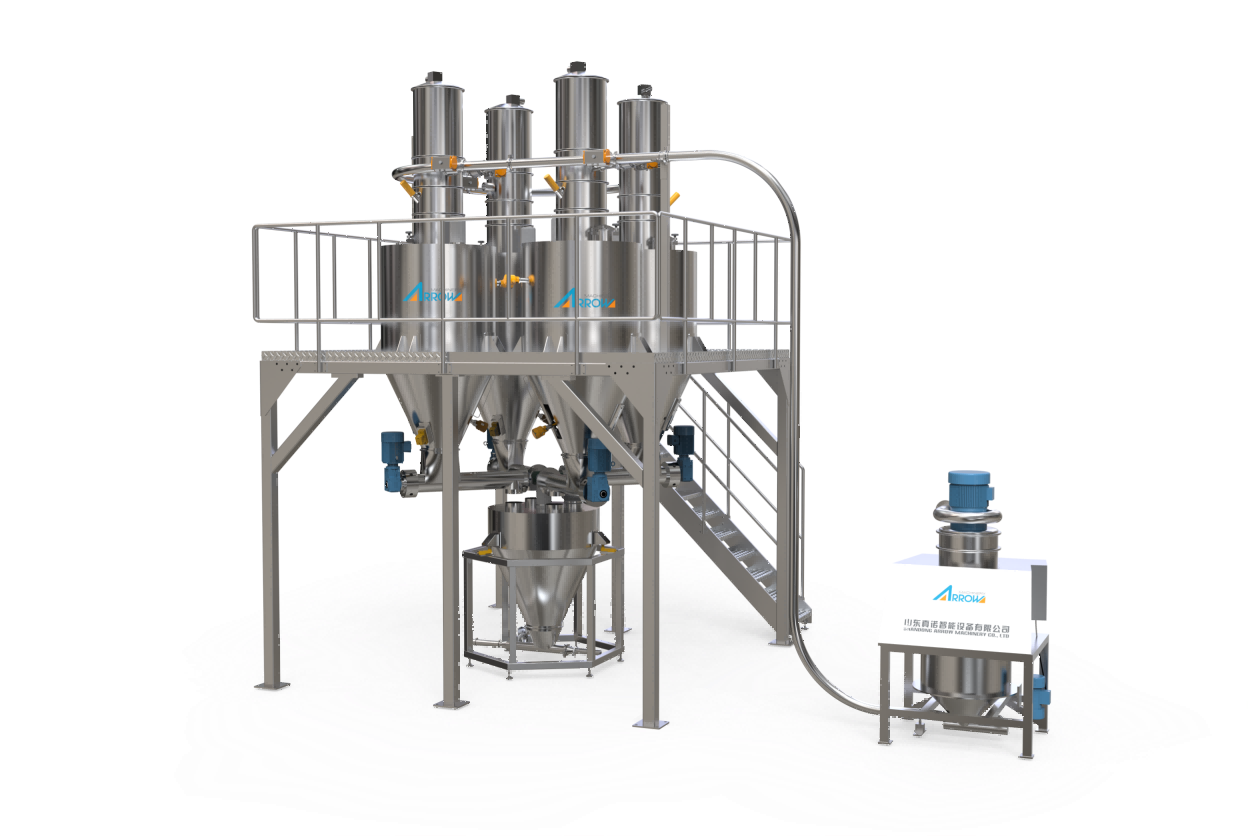

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02Adopting a double-layer rotor design, the mixing time is short, the uniformity is high, and the raw materials can be fully mixed. At the same time, a large section return air duct is equipped to reduce dust pollution.

-

Extrusion

03

Extrusion

03Through the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

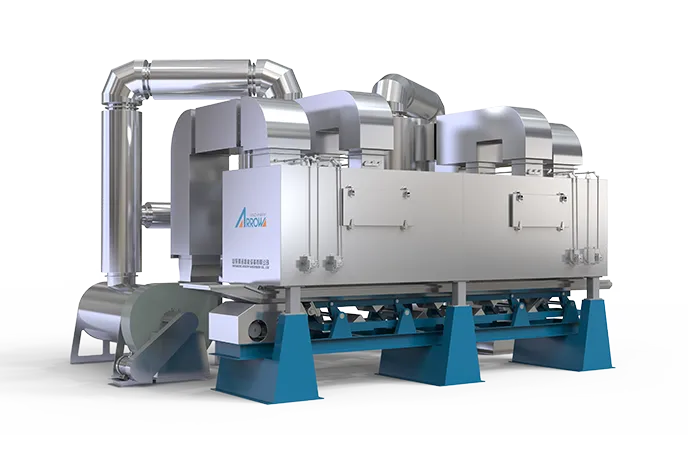

Dry Cooling

04

Dry Cooling

04The dryer features a forced hot air circulation system to improve thermal processing efficiency. The heat source can be a variety of heat media, including electricity, natural gas, fuel oil, and steam. The control system uses a PLC module for more precise temperature control.

-

Grinding

05

Grinding

05The product produced by the twin-screw extruder is crushed into powder by a grinder to ensure that the ingredients in the nutritional powder are evenly distributed, thereby improving the overall nutritional value and edible effect of the product.

Modified Starch

Our Industry Advantages

-

Over 30 Years Of Industry Experience

We have over 30 years of experience in the manufacturing of extruded foods and are familiar with global development trends. Through close cooperation with you, we provide you with a one-stop solution that suits you, including full process design, workshop layout design, and workshop construction guidance.

-

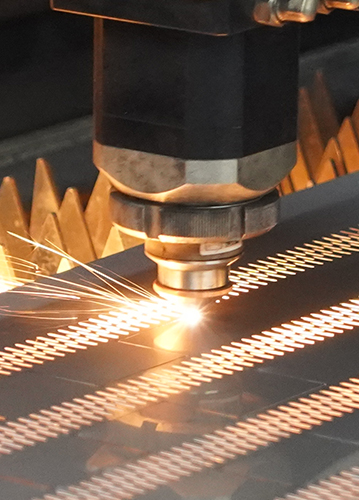

Leading The Production Frontier

We focus on creating intelligent, efficient, long-lasting, and low-energy fully automated production solutions to ensure stable system operation and lead the industry's technological forefront. Every process strictly follows food safety standards to safeguard your production.

-

Product Innovation

Our team of food technologists and engineers work closely together to keep pace with market trends and understand evolving tastes. We continuously innovate equipment and formulations to create tailored extruded food solutions that meet future market demands and help us pioneer new trends in the industry.

-

Global Quality Service

Our machinery and engineering services are available in over 110 countries and regions. Regardless of your location, you can expect responsive, attentive service. Our dedicated team is always on hand to resolve production issues, optimize your facility performance, and ensure a smooth and worry-free production journey.

Comprehensive Customized Engineering Solutions

Service Process

-

01

Inquiry

-

02

Design

-

03

Testing

-

04

Plan

-

05

Manufacturing

-

06

Logistics

-

07

Installation

-

08

Debug

-

09

Training

-

10

Turnkey Project

-

11

Service