-

Technical Design Services

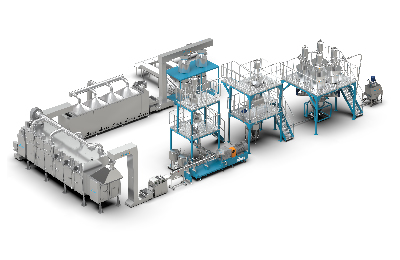

Arrow provides you with a one-stop solution, including full-process design, workshop layout design and workshop construction guidance.

Full process design we have our own mature and standardized production process, and we can also design the production process according to your needs. Factory layout design our engineers will prepare the full line layout according to your workshop. If the workshop is not uniform, we can also design the layout according to its shape and size. Factory construction guide our engineers will guide you on how to design and prepare the workshop building.

-

Product Process Services

Provide you with comprehensive, high-standard machine testing services and formula testing.

As a professional manufacturer of puffed food machinery, we rely on the powerful resources of Arrow Intelligent Extruded Food R&D Center and Jinan City Extruded Food Application Key Laboratory to provide customers with comprehensive, high-standard machine testing services and formula testing. We are well aware of the importance of food technology and formula, so we are committed to providing customers with complete and mature food solutions. From equipment testing to formula optimization, every step strives to be accurate and efficient, helping customers stand out in the fiercely competitive market.

-

Digital Services

"One-stop smart factory solution: ERP docking, efficient management and intelligent monitoring"

• Supports docking with the factory ERP system: production orders and data interaction can be realized with high compatibility.

• System performance: load balancing, high data connectivity and security, production process and network visualization diagnosis.

• Ingredient management: each warehouse parameter can be set individually and can be adaptively dynamically optimized. The system can change the formula without stopping the machine and has a power-off protection function.

• Data management: alarm information, operation records, and energy consumption data can be recorded.

• Warehouse capacity management: bulk warehouse materials, silo outbound warnings, query reports, and calculate raw material losses can be monitored. -

Operation training

We provide professional training on equipment operation and maintenance

Practical operation: Our professional engineers will personally guide customers to operate the equipment to ensure that your team members are proficient in every step from startup to shutdown. Safety specification explanation: Detailed explanation of various safety specifications in equipment operation, including safety inspections before startup, precautions during operation, and safety maintenance after shutdown, etc., to ensure that each step of the operation meets safety standards. Troubleshooting and resolution: In-depth explanation of the identification, cause analysis and quick solutions of common equipment failures, to enhance customers' ability to respond to emergencies and ensure the continuous and stable operation of the production line. Maintenance skills: Teach the key points and skills of daily equipment maintenance, including key steps such as cleaning, lubrication, and tightening, to extend the service life of the equipment and reduce maintenance costs.

-

Maintenance

Our specially trained engineers will perform maintenance on your equipment.

In the pursuit of efficient and stable production, equipment maintenance is crucial. To this end, we have equipped a team of top-notch and professionally trainedTrainingOur team of engineers not only understands the working principles and maintenance techniques of various equipment, but also has rich practical experience, and can quickly and accurately identify and solve any problems encountered in equipment operation. Once a device fails, we promise to respond immediately, diagnose and repair the fault to ensure uninterrupted production.

-

Accessories Support

We offer a full range of original accessories

All accessories are manufactured in strict accordance with original factory standards and undergo rigorous quality testing to ensure precise matching with your equipment, extend equipment life, and reduce failure rates. We have a complete accessories inventory system that can quickly respond to your needs and ensure timely delivery of accessories. At the same time, our professional after-sales service team will provide you with a full range of accessories installation, commissioning and technical support, so that you have no worries.

-

Upgrade

Provide comprehensive and flexible upgrade services for your equipment

We provide comprehensive equipment upgrade solutions, from the replacement of core components to the intelligent upgrade of control systems, to the overall optimization of production lines, to comprehensively improve equipment performance, increase production efficiency, reduce operating costs, and tailor-make suitable upgrade solutions. In addition to comprehensive upgrades, we also provide flexible partial upgrade services. If your equipment has bottlenecks in a certain link or requires specific functional enhancements, our professional team will conduct precise analysis and recommend the most suitable upgrade components or modules to achieve a balance between performance and cost.

- Home

- About Arrow

- Solution

-

Product

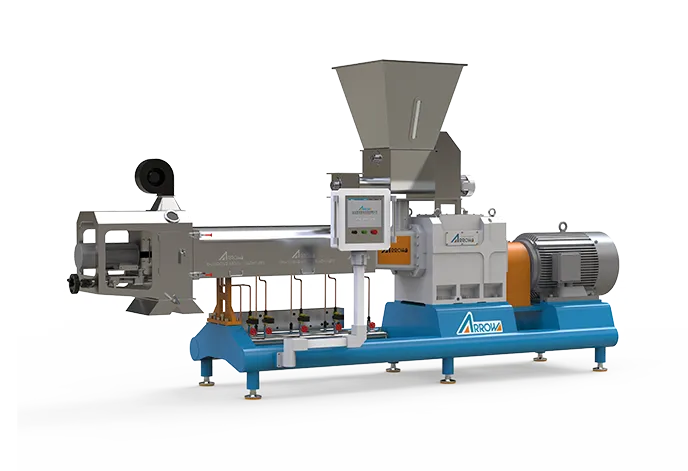

Twin Screw

-

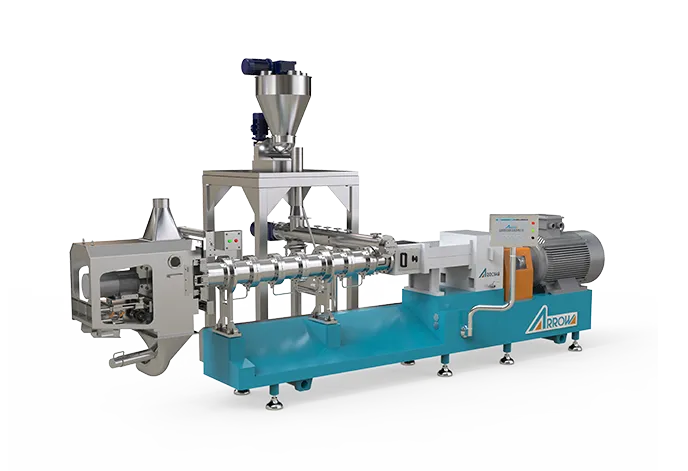

AYE Series Twin Screw Extruder

-

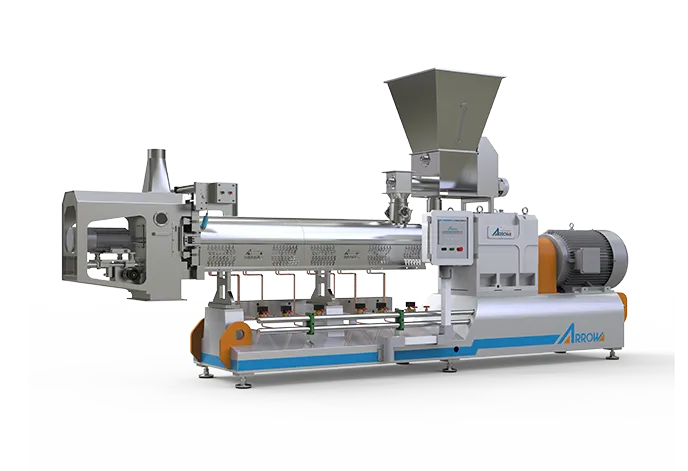

AHE Series Twin Screw Extruder

-

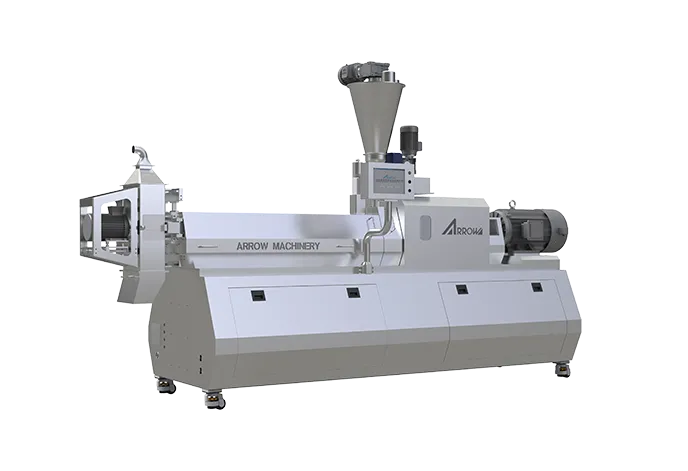

AYT Series Twin Screw Extruder

-

AHT Series Experimental Twin Screw Extruder

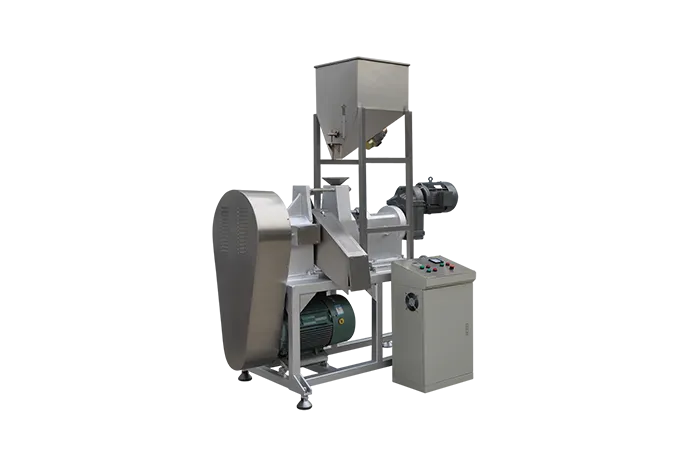

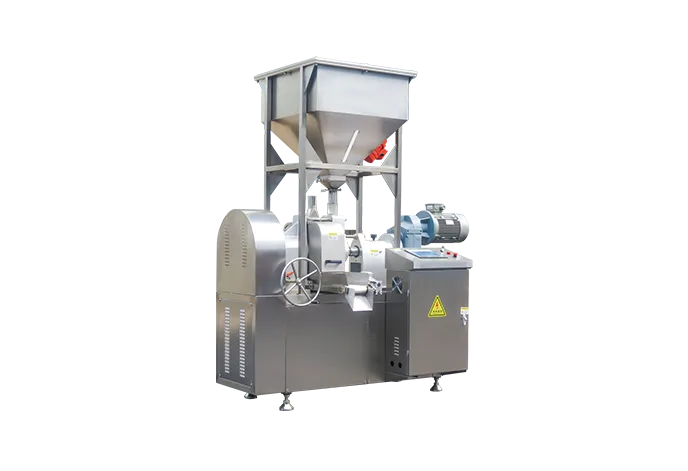

Single Screw

TS Extrusion

Dryer Series

-

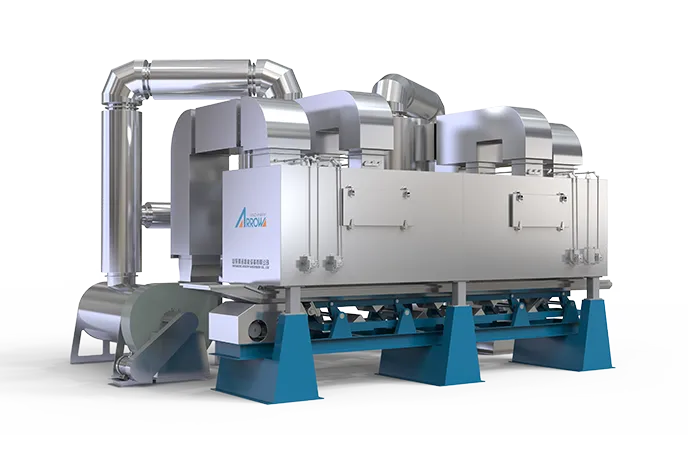

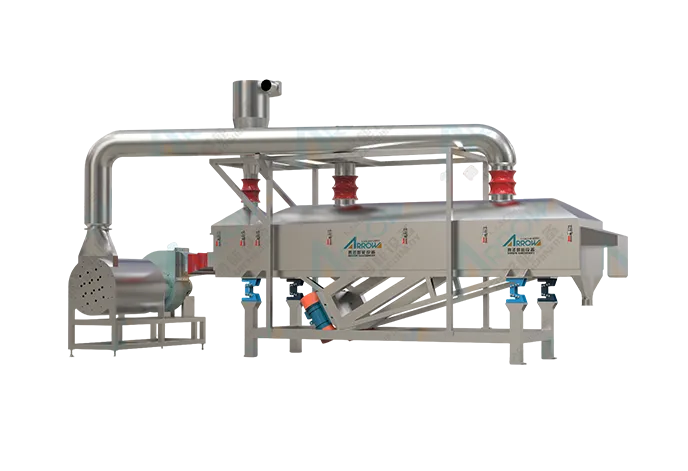

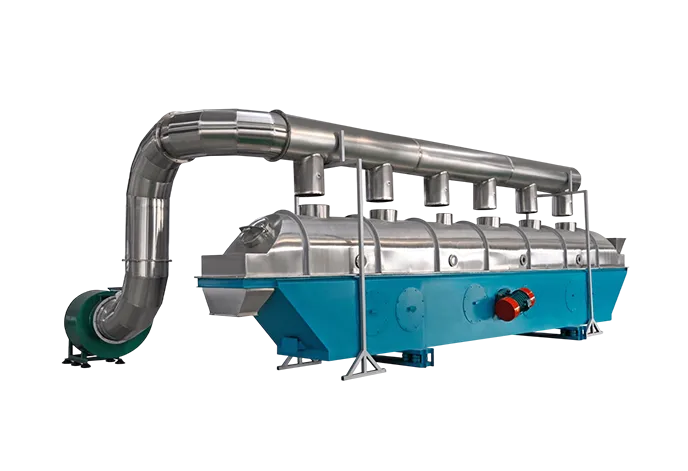

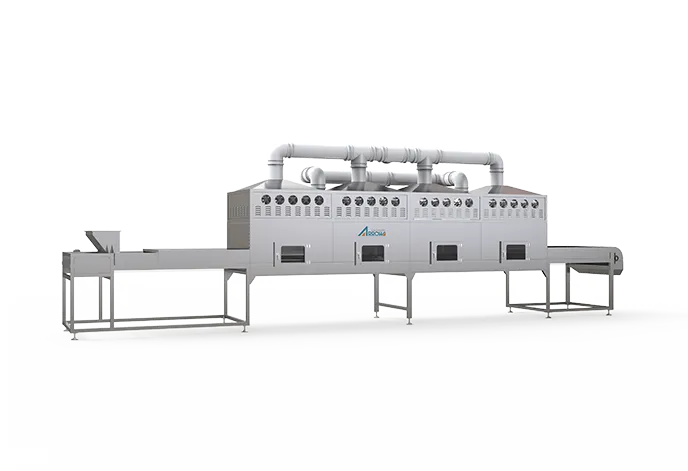

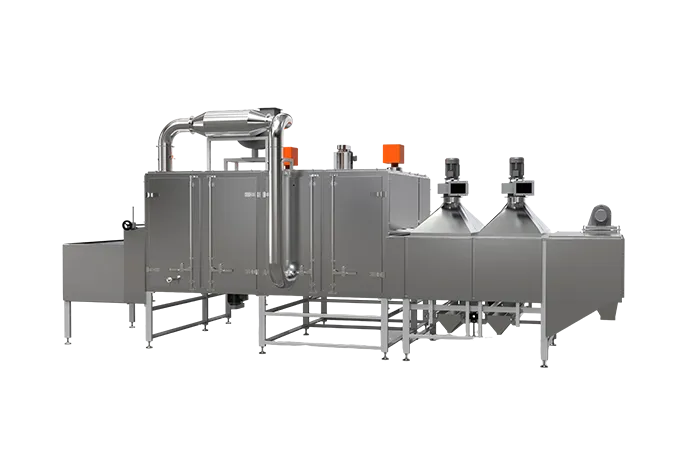

GKH Series Air Circulation Dryer

-

GSH Series Cross Circulation High Efficiency Dryer

-

GDH Series Single Layer High Efficiency Dryer

High Temperature Baking Machine

Vibration Drying

Other dryers

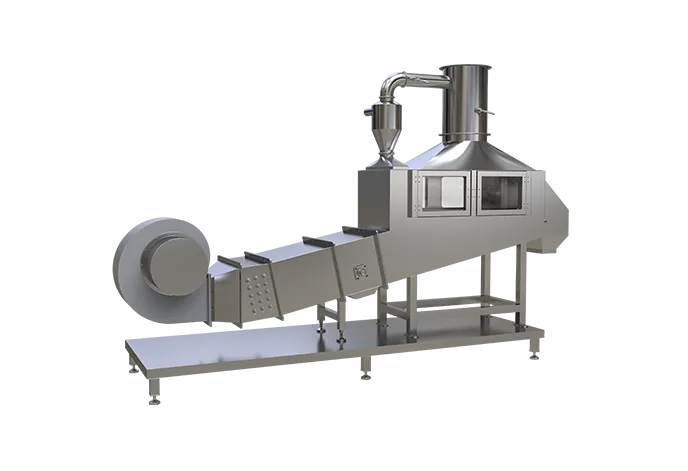

Crushing System Series

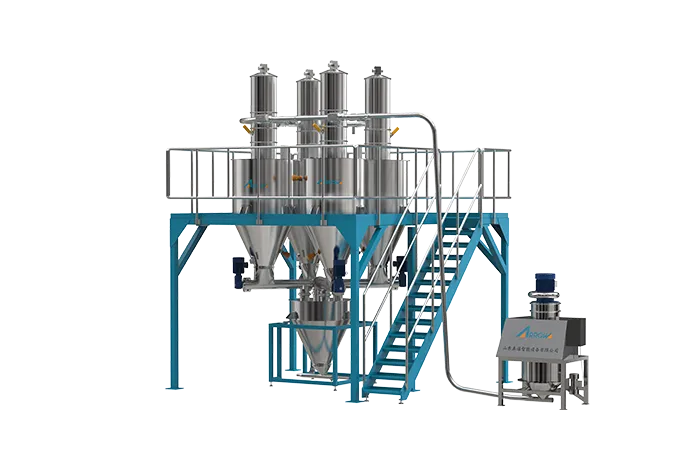

Weighing Batching Series

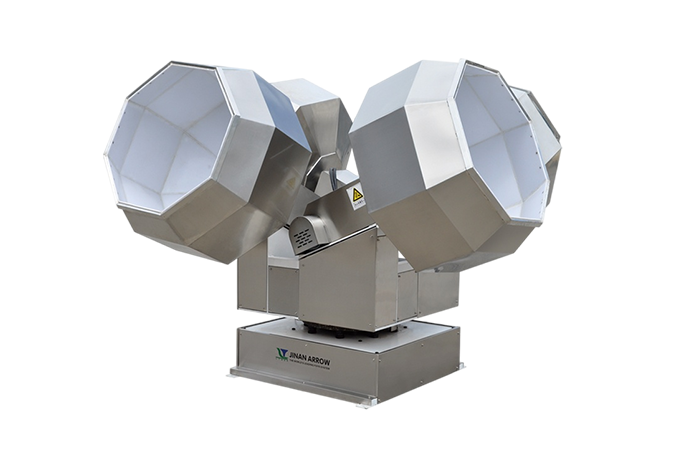

Mixed Series

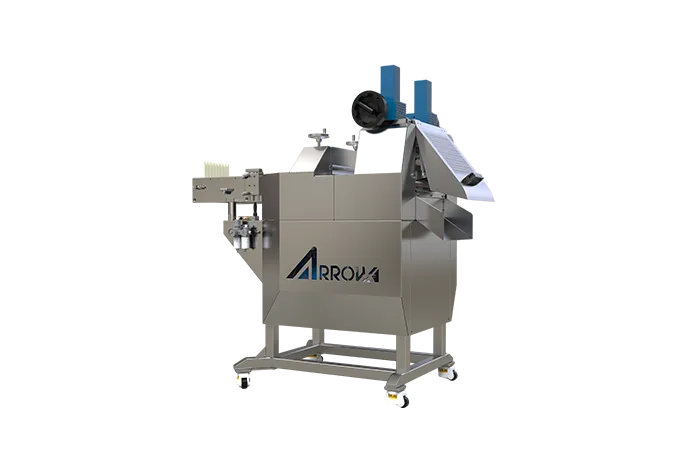

Triangle Sheet Forming Machine

Four-roll Forming Machine

Composite Molding Machine

Small Pillow Cutting Machine

Protein Cutting Machine

Pop Rice Cake Machine

-

- Manufacturing

- Support

- News

- Contact Us