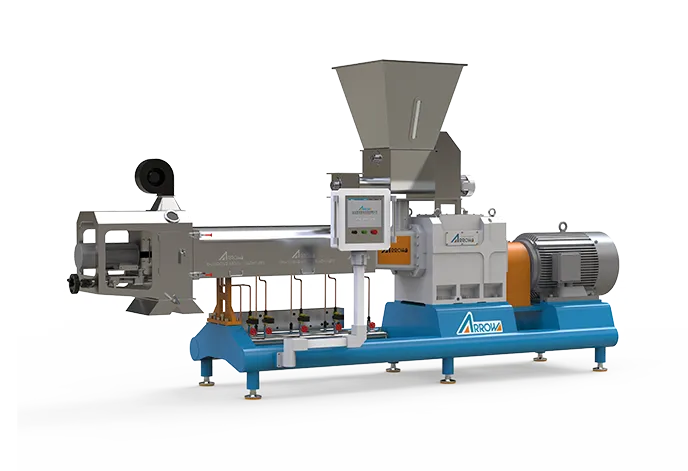

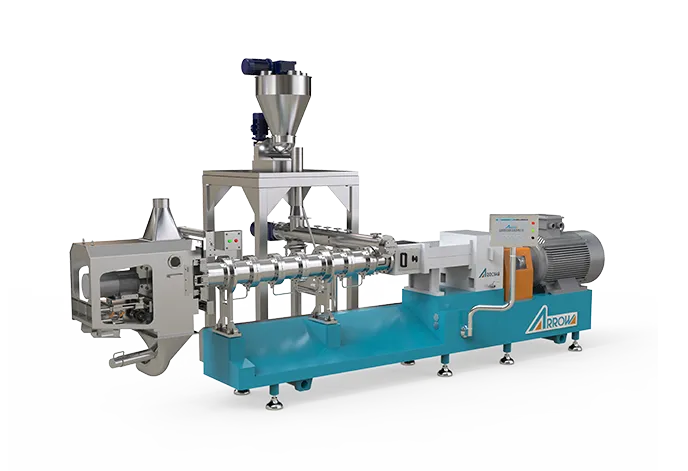

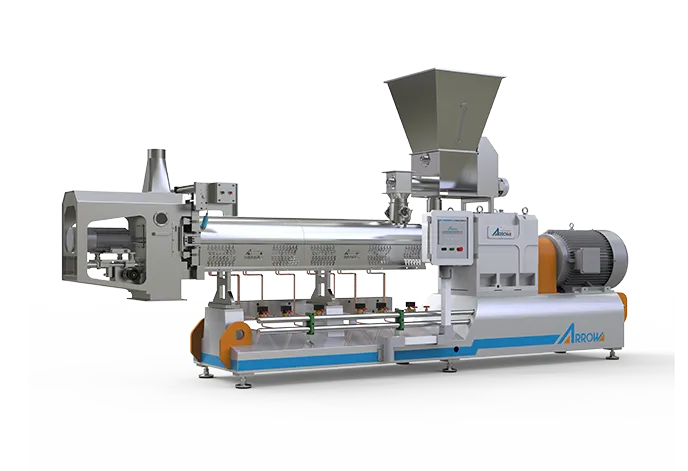

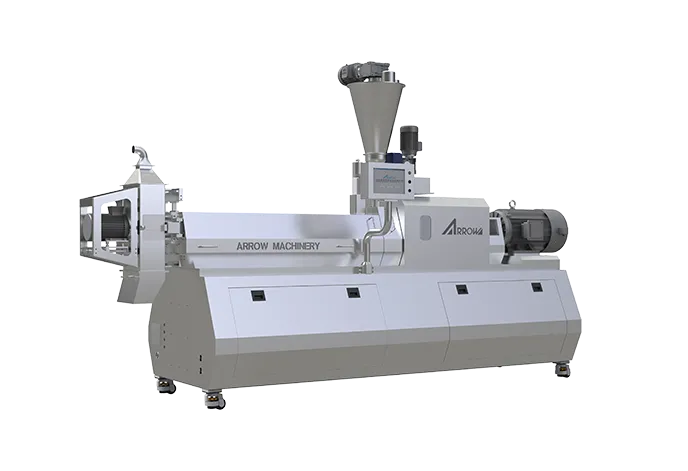

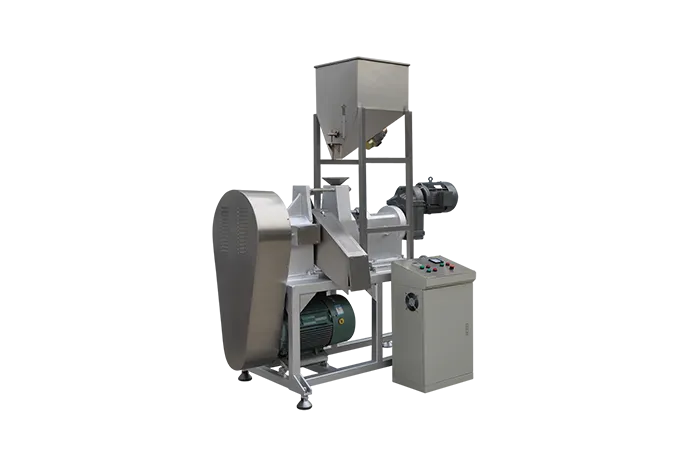

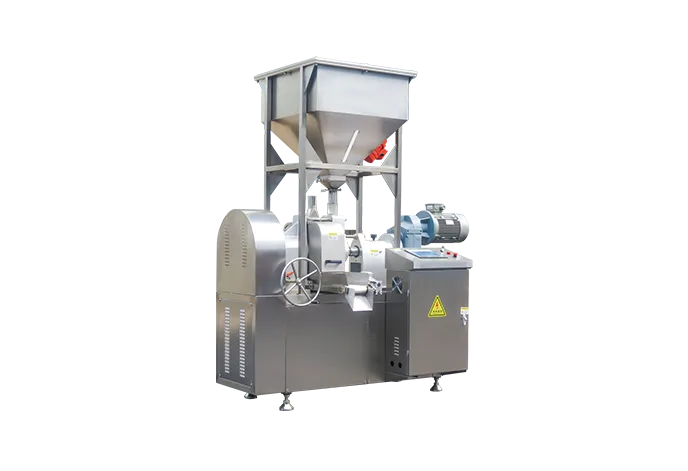

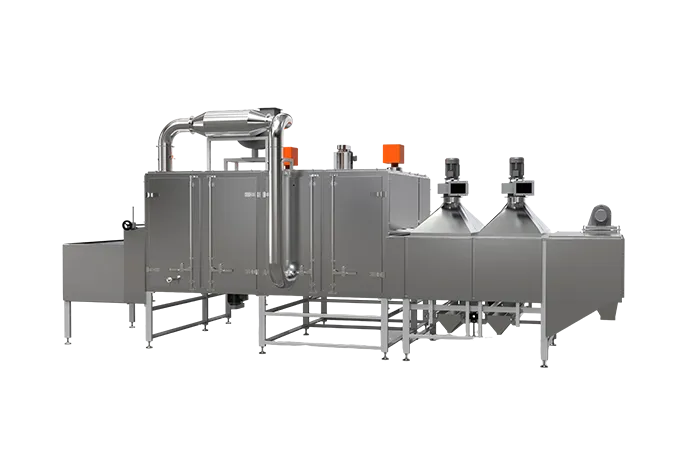

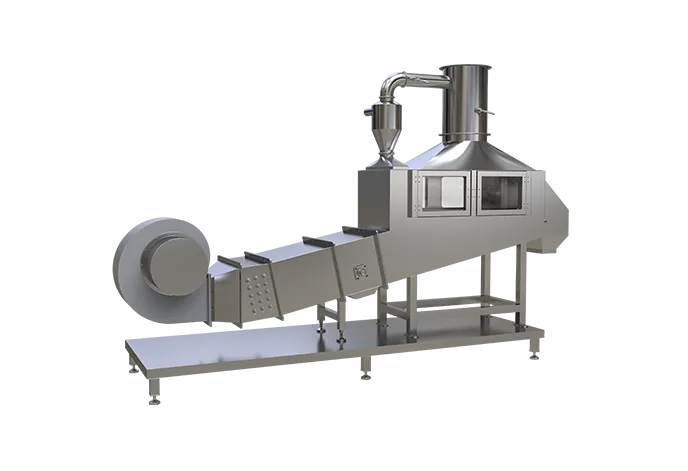

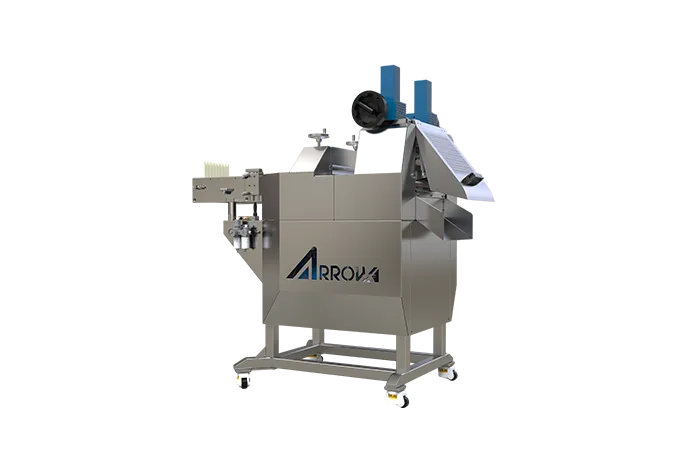

Cold Extrusion Machine

Cold Extrusion Machines are primarily used for products requiring low-temperature molding. They can utilize various cooling media for low-temperature extrusion, maintaining the material's composition and properties, while achieving simple extrusion molding.

Advantages:

1. Controllable extrusion temperature. Equipped with different cooling media, the low-temperature extrusion required by the raw material can be achieved.

2. A wide range of ingredients can be formulated to accommodate ingredients such as grain powder, milk powder, protein powder, fresh meat and meat powder, soy flour, fiber, and other trace nutrients.

3. Product shapes are diverse. By adjusting the formulation and mold design, various shapes and hardness levels of pellets, bars, and flakes can be produced.