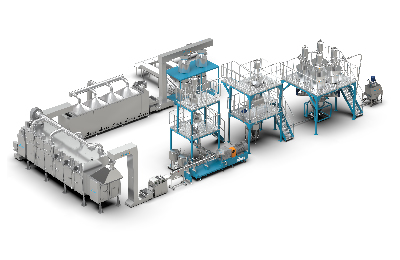

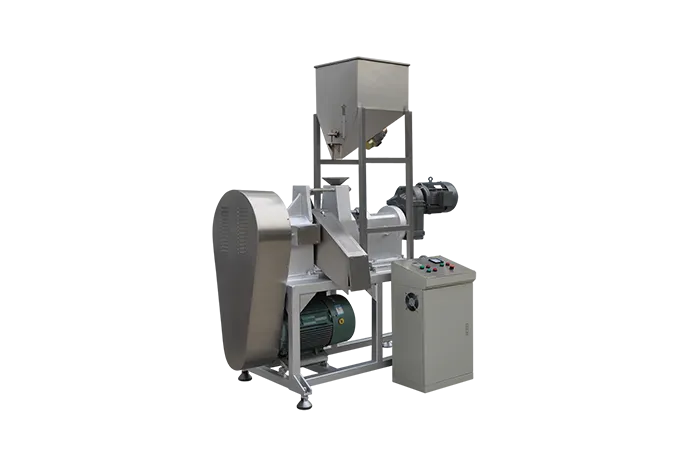

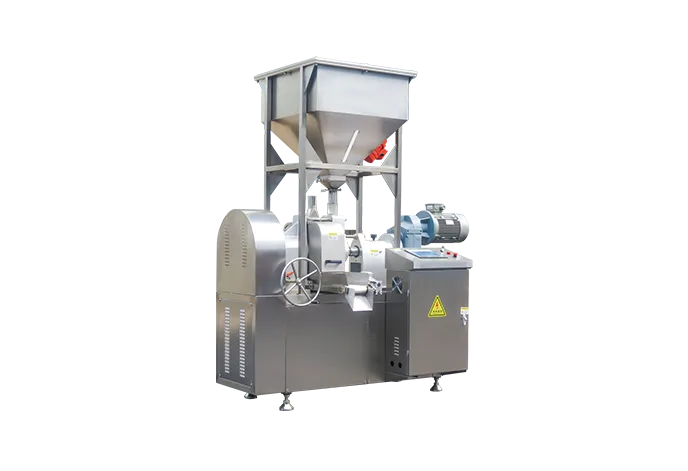

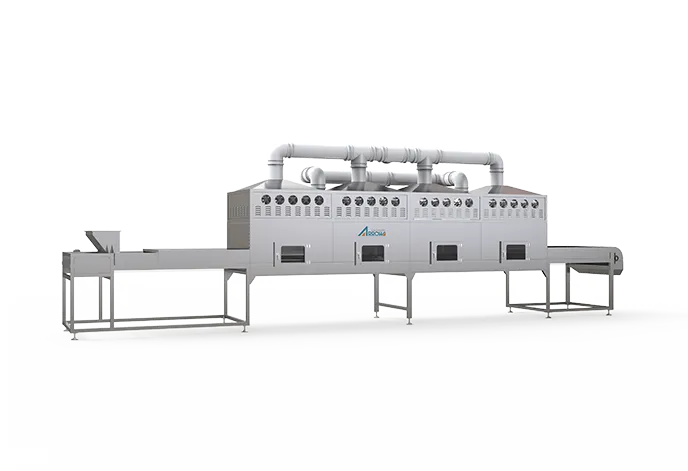

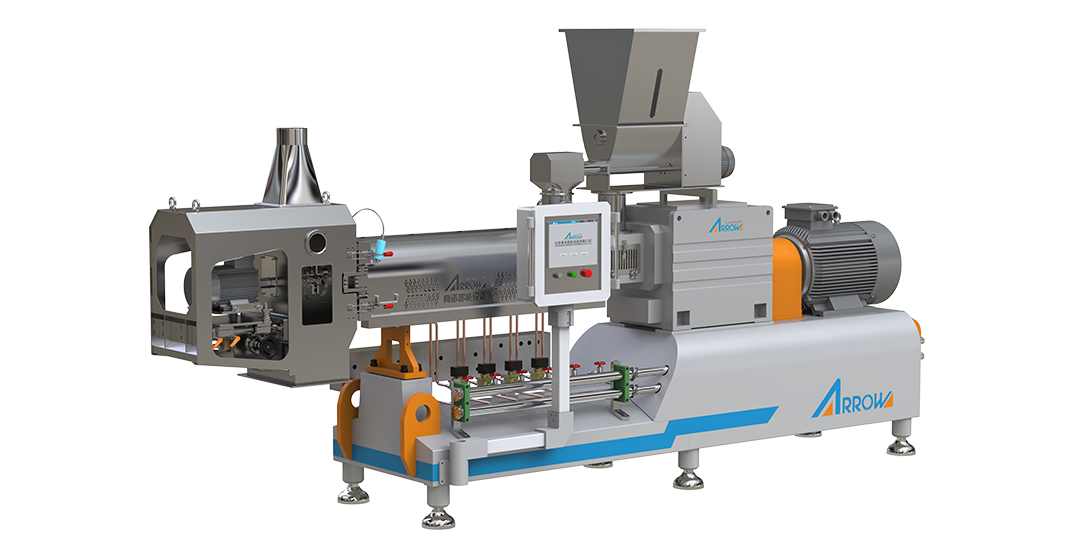

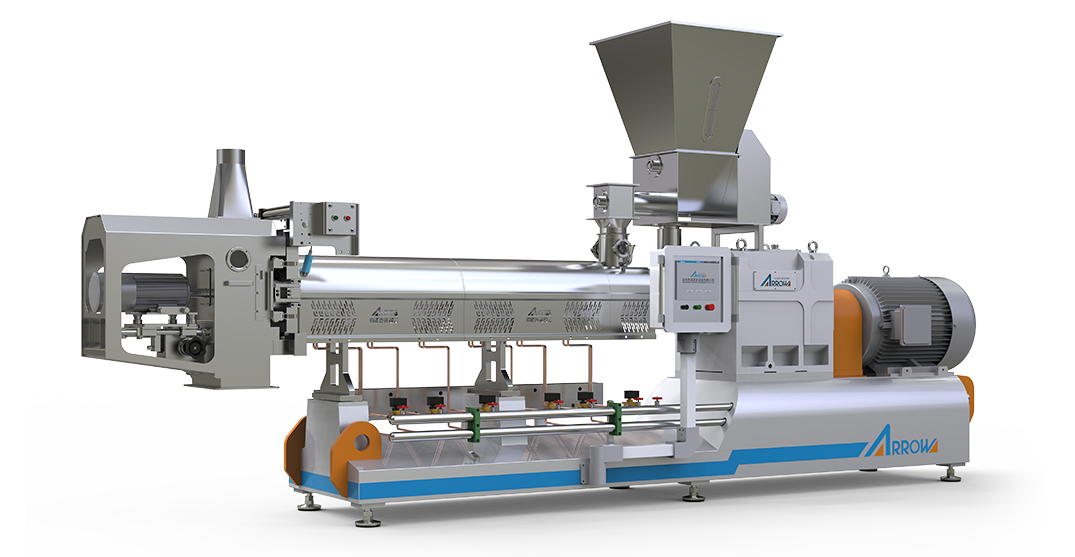

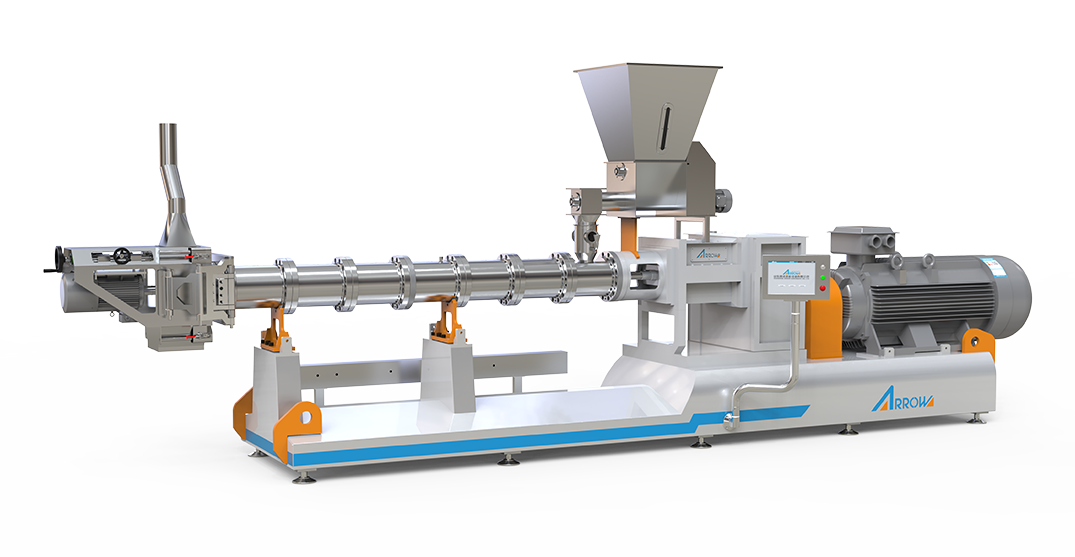

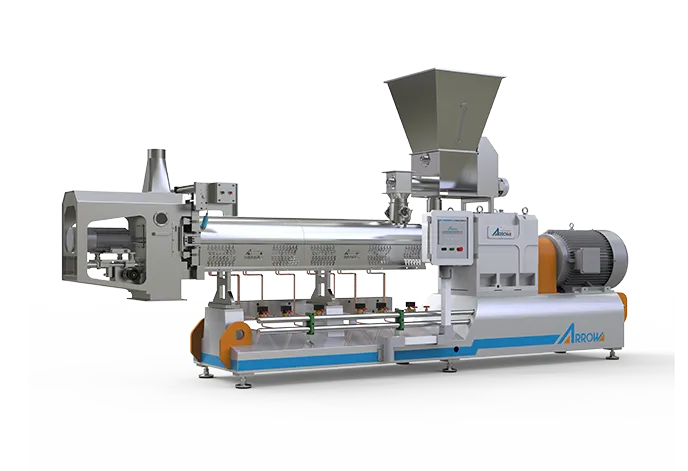

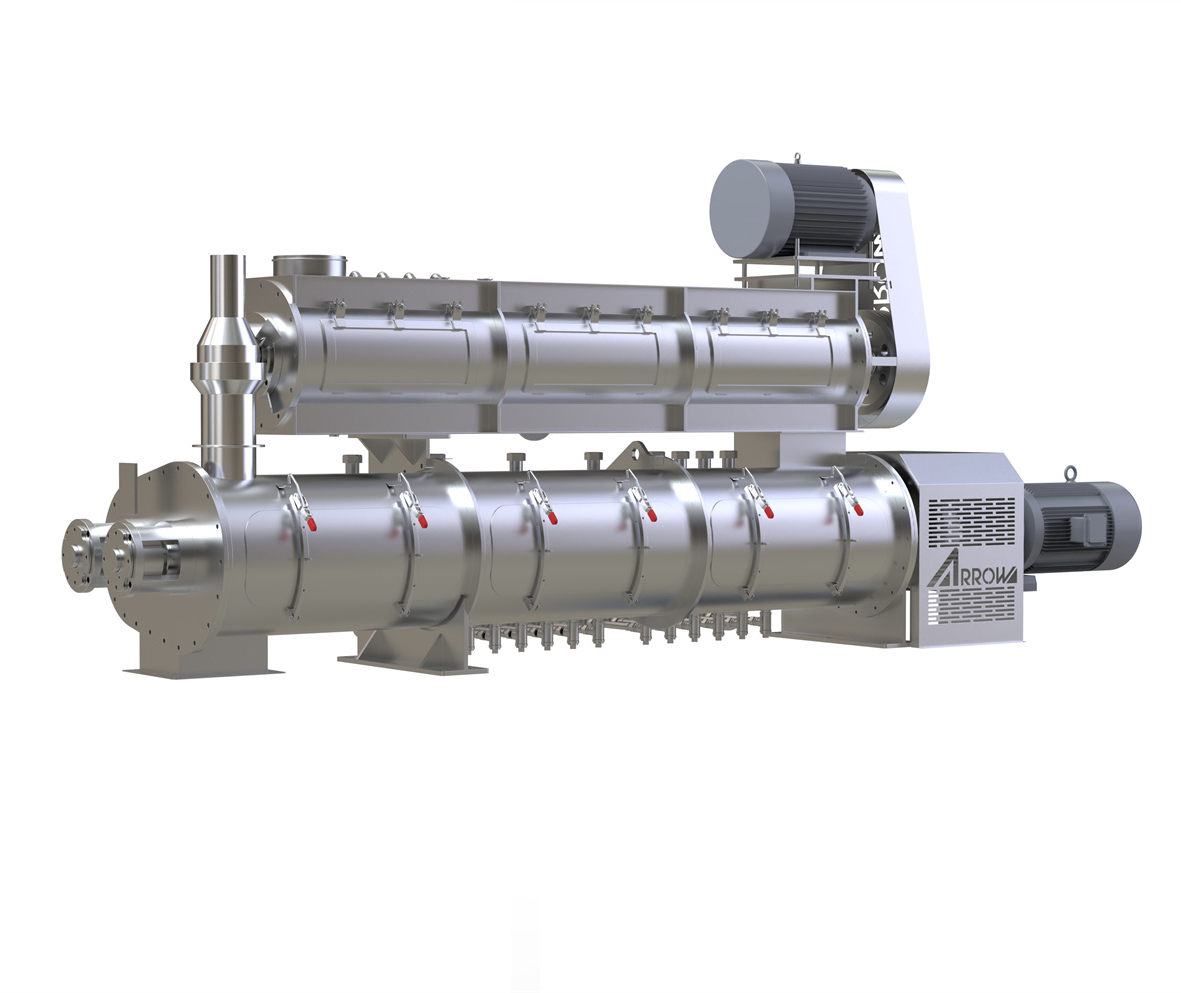

AYT Twin Screw Extruder

The AYT series is mainly applied in pet food and special aquatic feed, with large production and unique appearance. It has advantages in convenient processing of high fresh meat and high protein pet food, which can improve the palatability and durability of pet food.

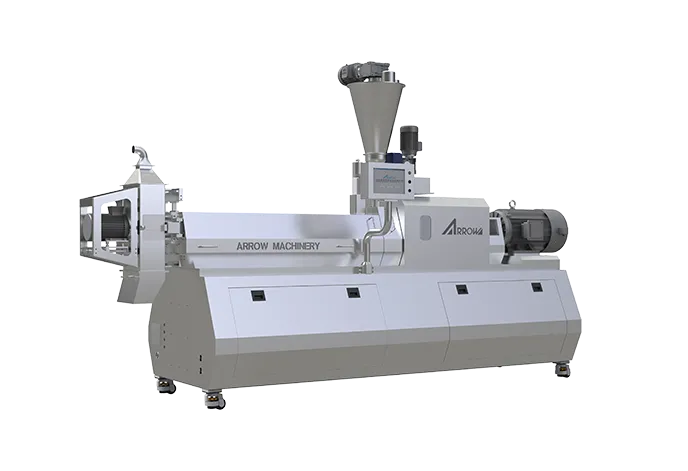

The twin-screw extruder is an innovative equipment in the modern food industry, designed specifically for producing diversified puffed foods.

Adopting advanced twin-screw structure, it can fully mix and plasticize raw materials under high temperature and high pressure. When the raw materials reach the discharge port, pressure release and temperature drop convert the internal moisture into steam, forming tiny bubbles that rapidly expand the food and make it crispy in taste.

This device is suitable for various raw materials, can flexibly adjust process parameters, produce a variety of puffed products, and has the characteristics of high efficiency, intelligence, and easy cleaning, promoting innovation and upgrading in the food industry.

Equipment Advantages

-

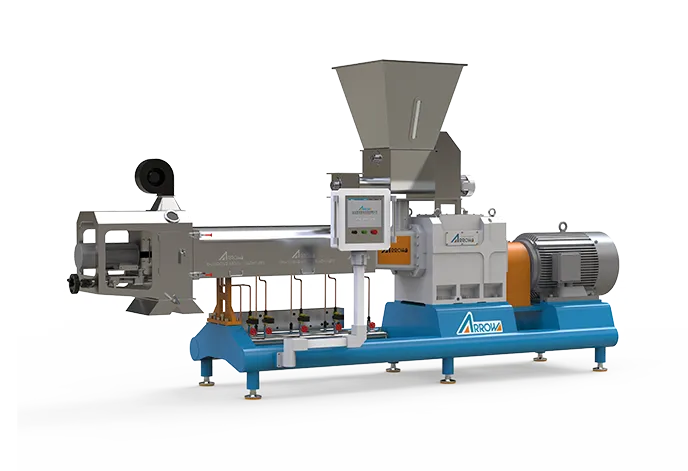

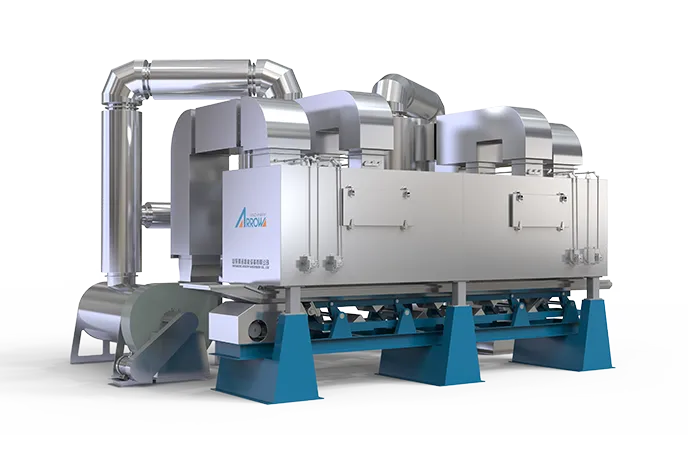

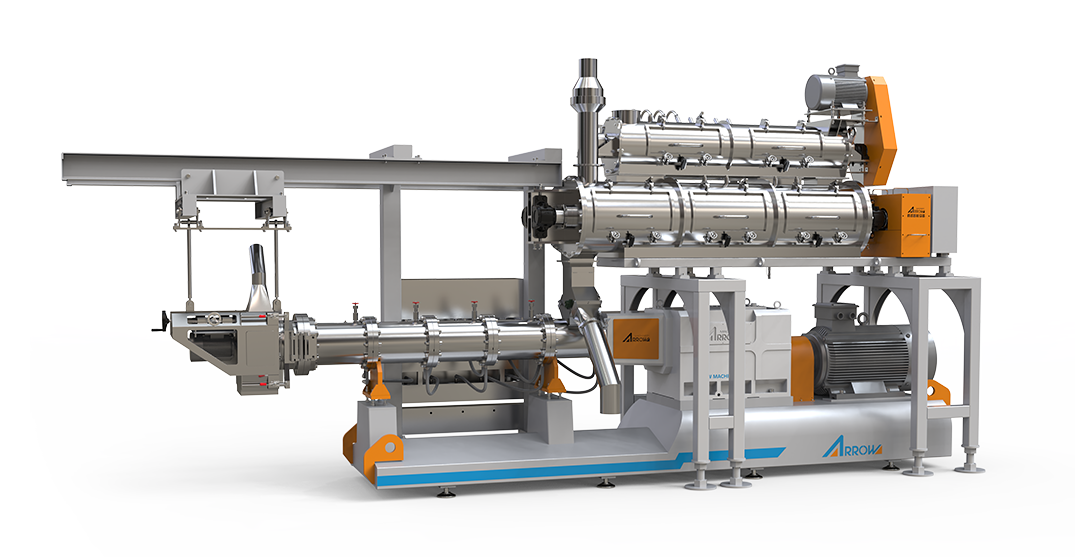

High Speed High Torque Transfer Case

0101High Speed High Torque Transfer Case

The power distribution adopts a high speed high torque transfer case. Strong carrying capacity, low noise index, and high efficiency.

-

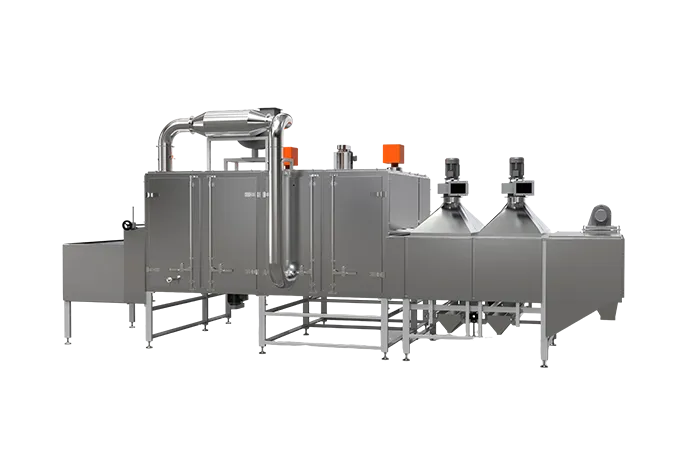

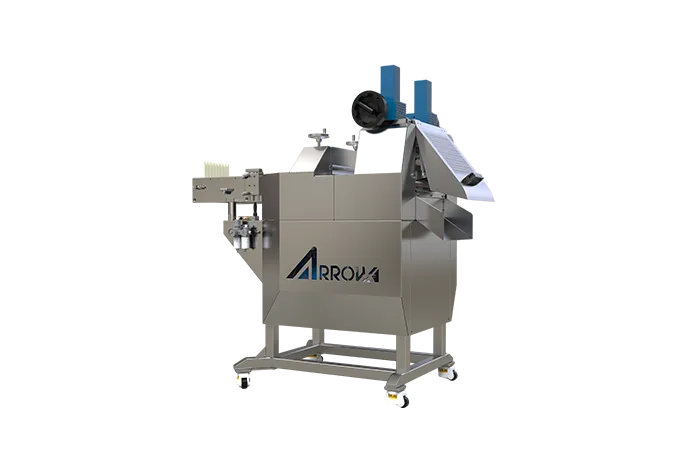

Triple Shaft Paddle Conditioner

0202Triple Shaft Paddle Conditioner

The material conditioning adopts a triple shaft paddle conditioner with multiple liquid and steam addition ports to ensure uniform conditioning of the material and improve the proportion of fresh meat added and the aging effect.

-

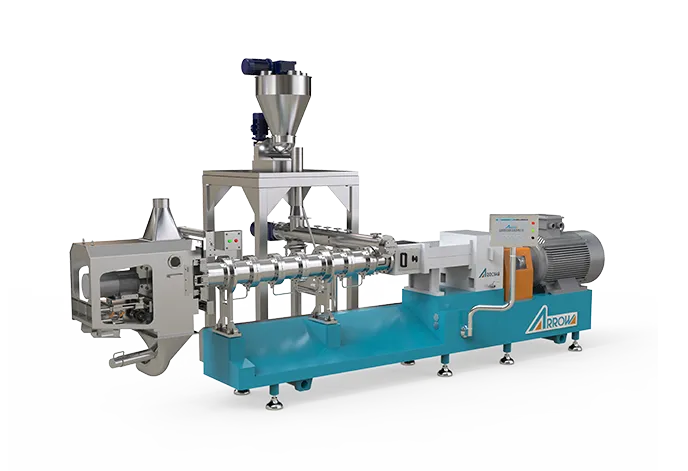

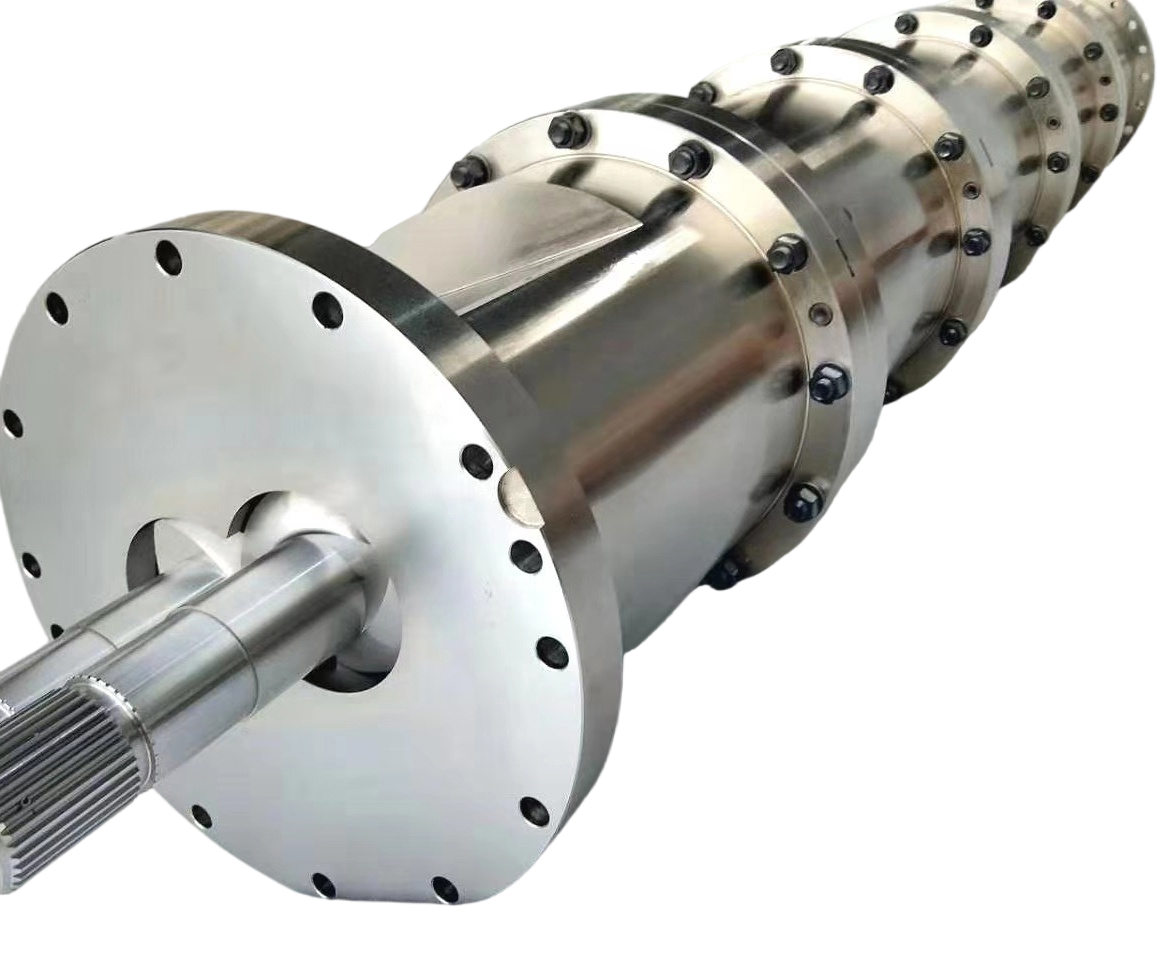

Building Block Barrel Screw

0303Building Block Barrel Screw

The material shearing and extrusion adopts the combined building block type barrel and screw, which are made of food grade alloy and have higher wear resistance and corrosion resistance.

-

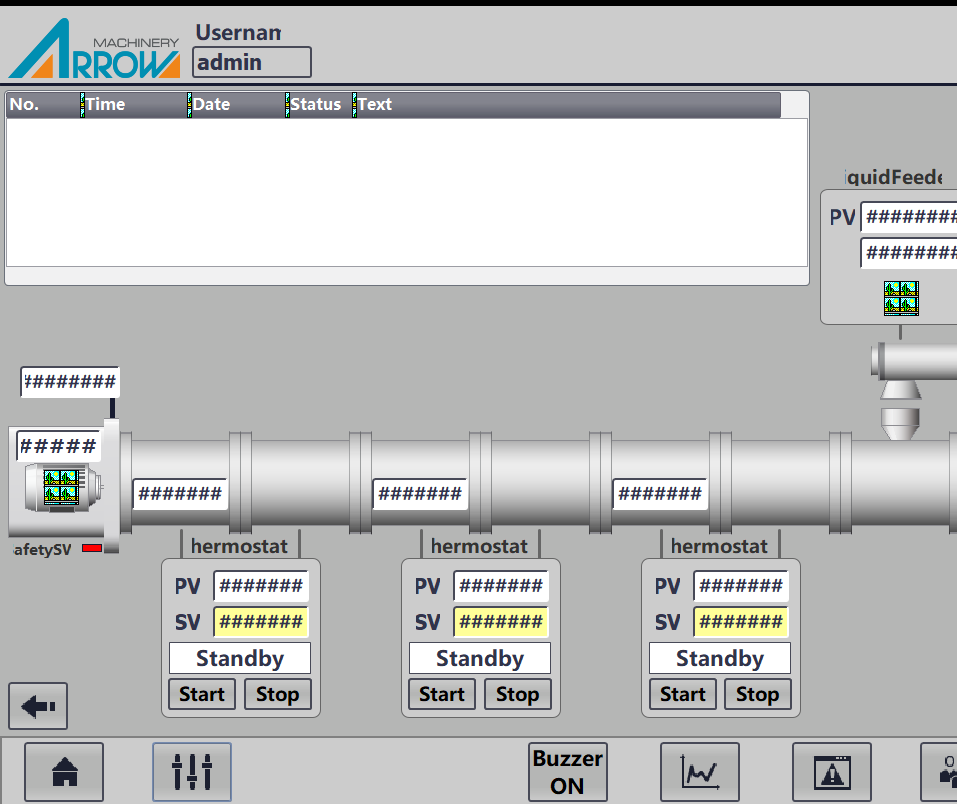

Friendly Human-Machine Interface

0404Friendly Human-Machine Interface

The control module adopts a friendly human-machine interface, rich data display and memory storage.