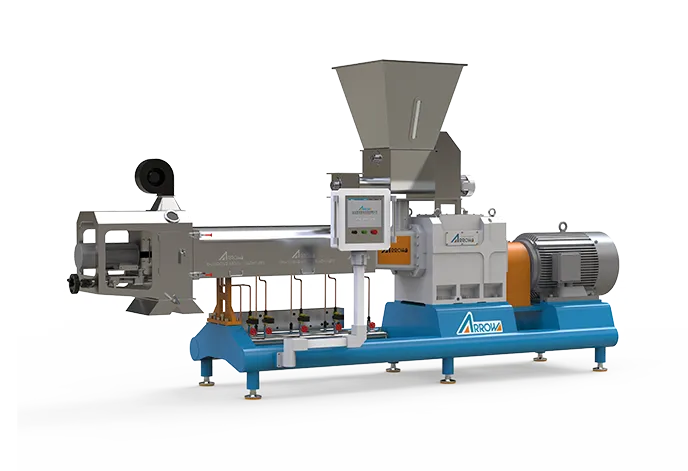

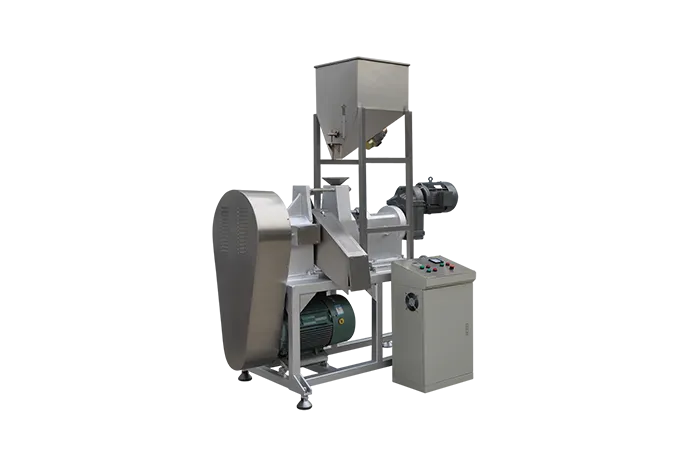

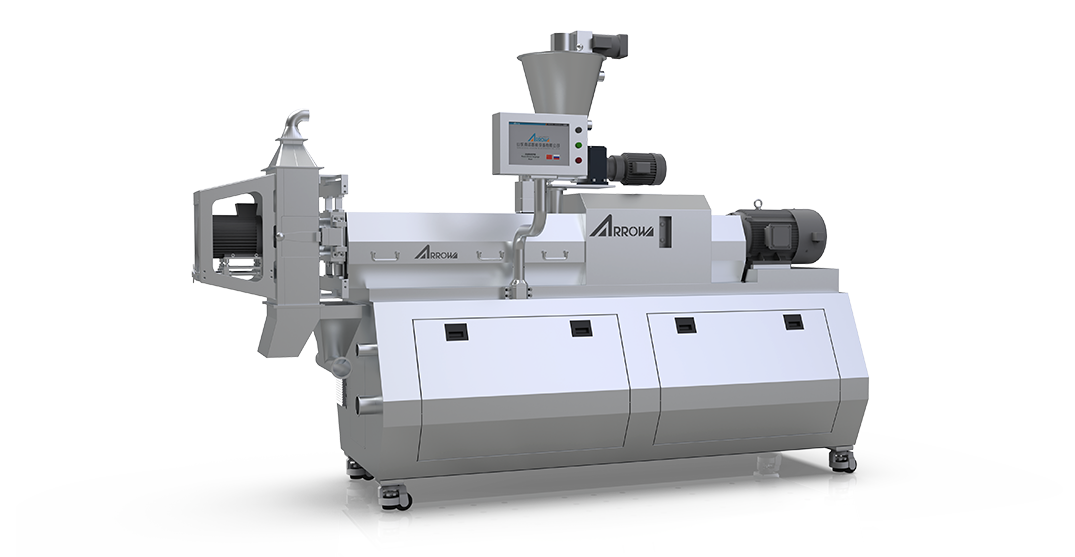

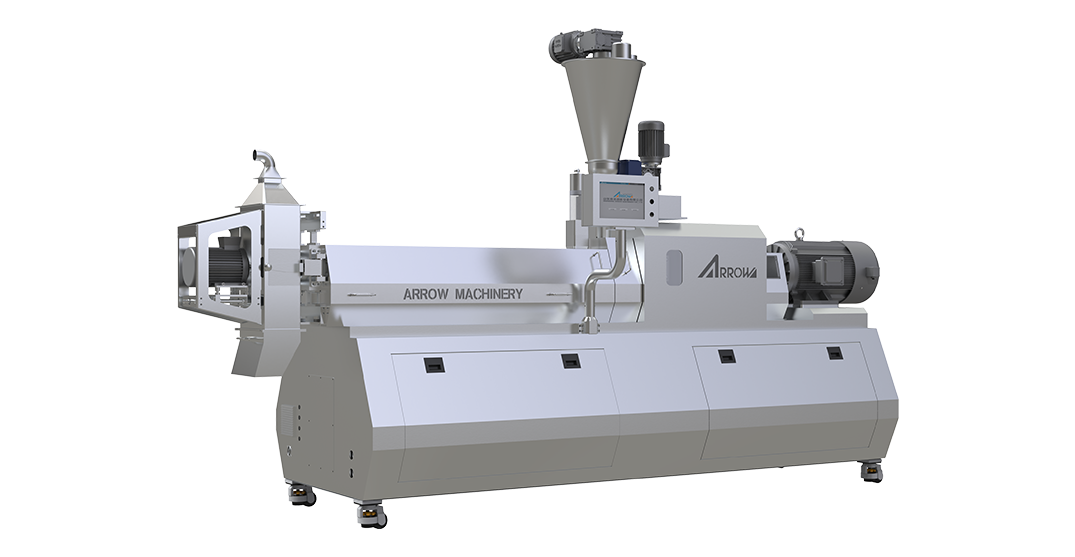

Experimental Twin Screw Extruder

The experimental twin-screw extruder is a multifunctional experimental equipment designed specifically for scientific research and teaching.

The main features of the experimental twin-screw extruder include powerful functions, easy operation, flexible parameter adjustment, accurate experimental data, and easy maintenance and repair. Its design considers the processing requirements of various raw materials, such as grains, potatoes, starch, protein, chemical raw materials, plastics, and rubber, and can adapt to these diverse raw materials for various experiments.

The technical parameters of experimental twin-screw extruder usually include screw diameter, screw center distance, screw material, speed range, barrel heating method, temperature range, pressure range, etc. These parameters can be adjusted according to experimental needs to meet the requirements of different raw materials and experimental conditions.

Equipment Advantages

-

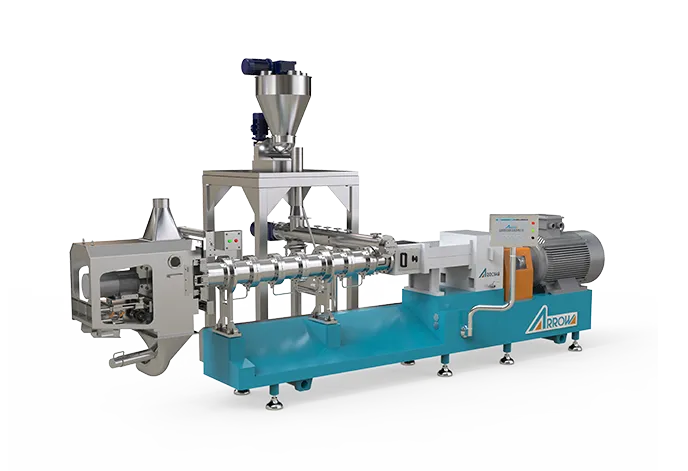

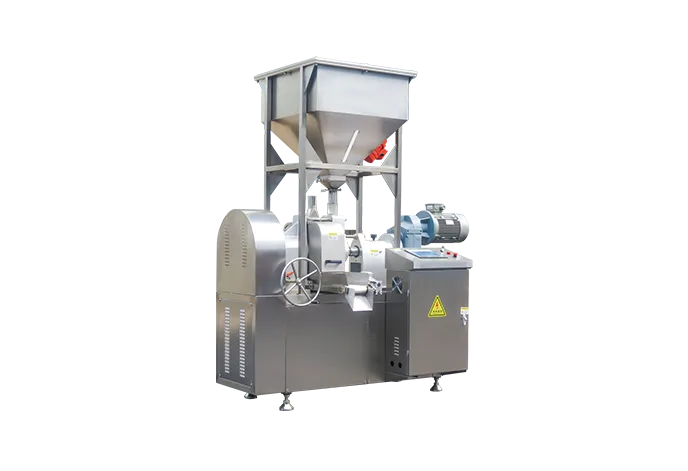

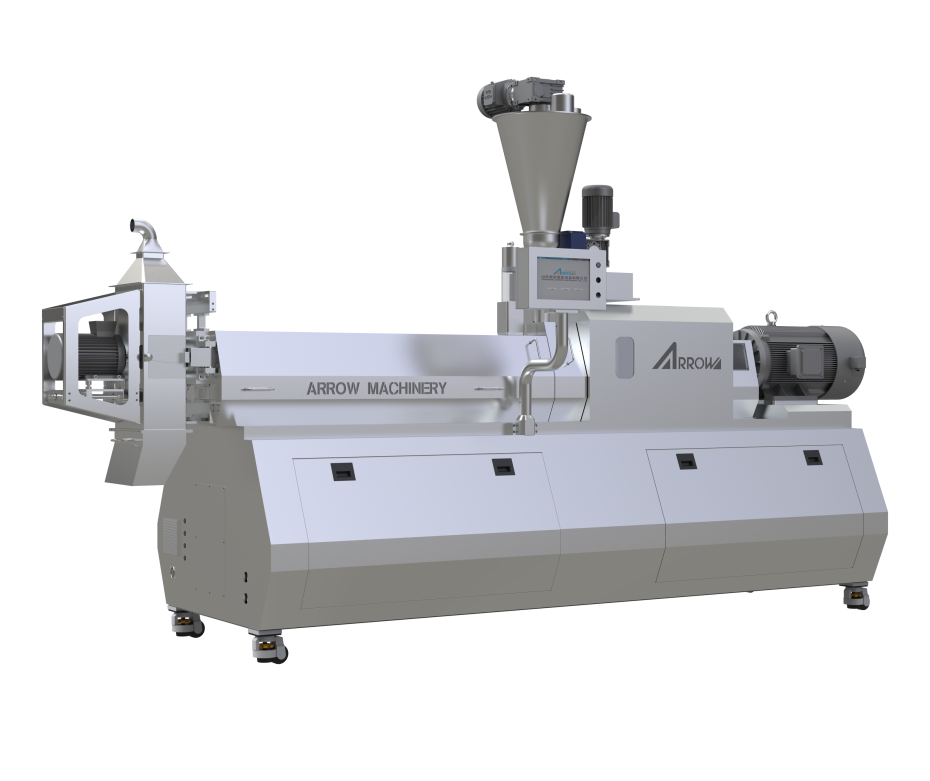

Small Footprint Low Operating Costs

0101Small Footprint Low Operating Costs

The machine is compact and has controllable output. 5-10KG of materials are enough to complete a single batch of experiments, reducing investment in research and development funds.

-

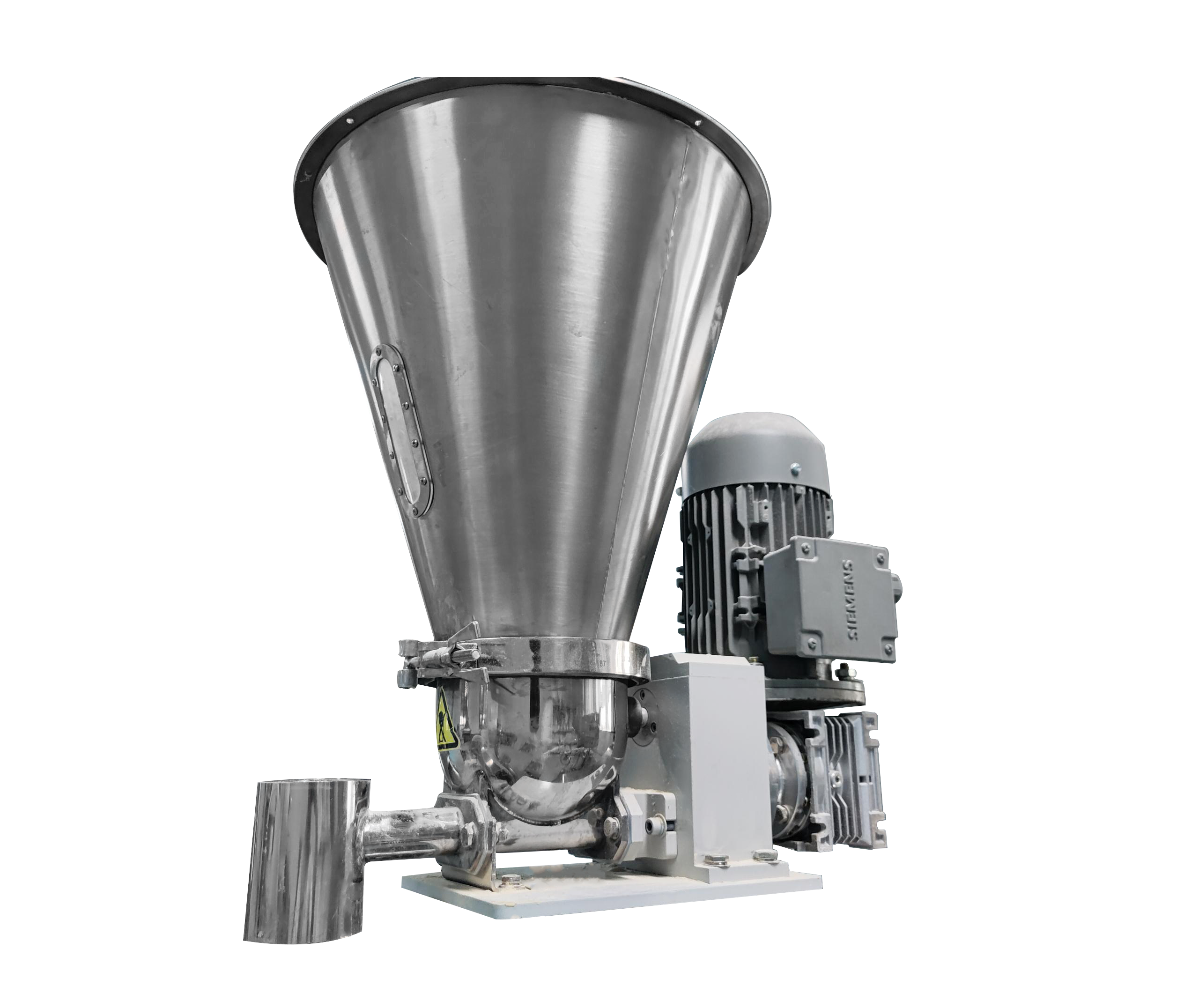

Precise Measurement

0202Precise Measurement

Weighing type metering feeding, accurate measurement, automatic calculation of the feeding amount according to the specific gravity of different materials, suitable for testing materials with different proportions.

-

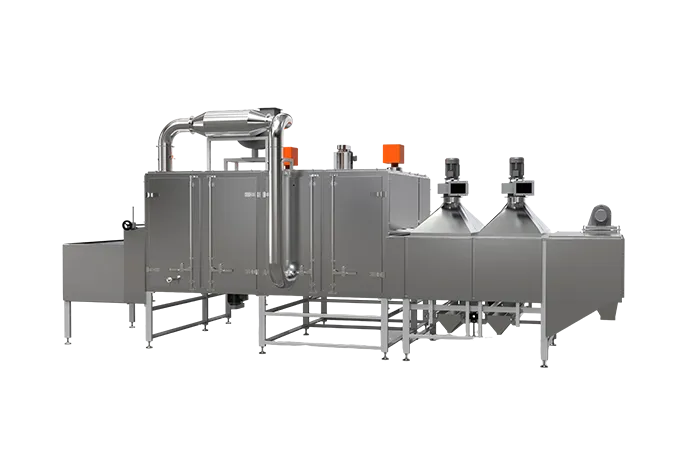

Standard Brand High Torque Gearbox

0303Standard Brand High Torque Gearbox

Eliminate oil leakage, high noise, abnormal sound and other problems of ordinary gearboxes and improve the stability and reliability of the equipment.

-

High Automation

0404High Automation

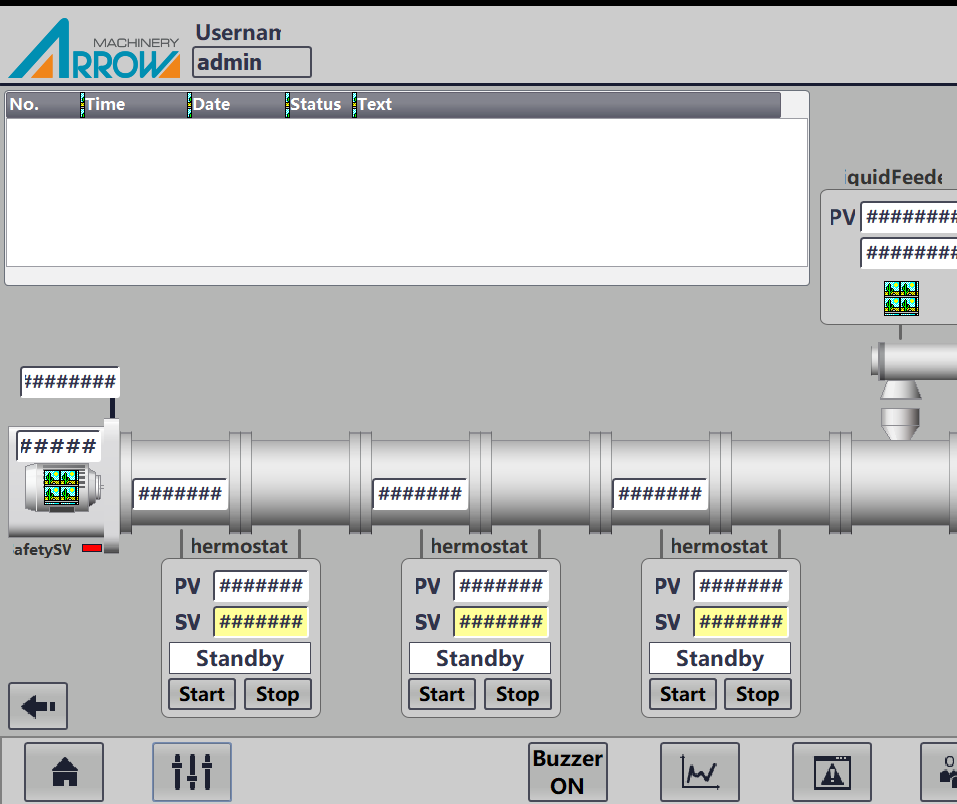

PLC control, easy to operate. It can remotely control the operation of equipment on the PC end of the computer and has functions such as processing system alarms, viewing alarm data, alarm shutdown protection, and implementing a one click start/stop program for the entire system.