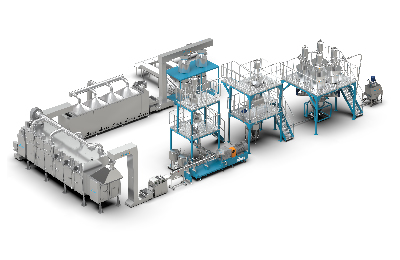

Solution Introduction

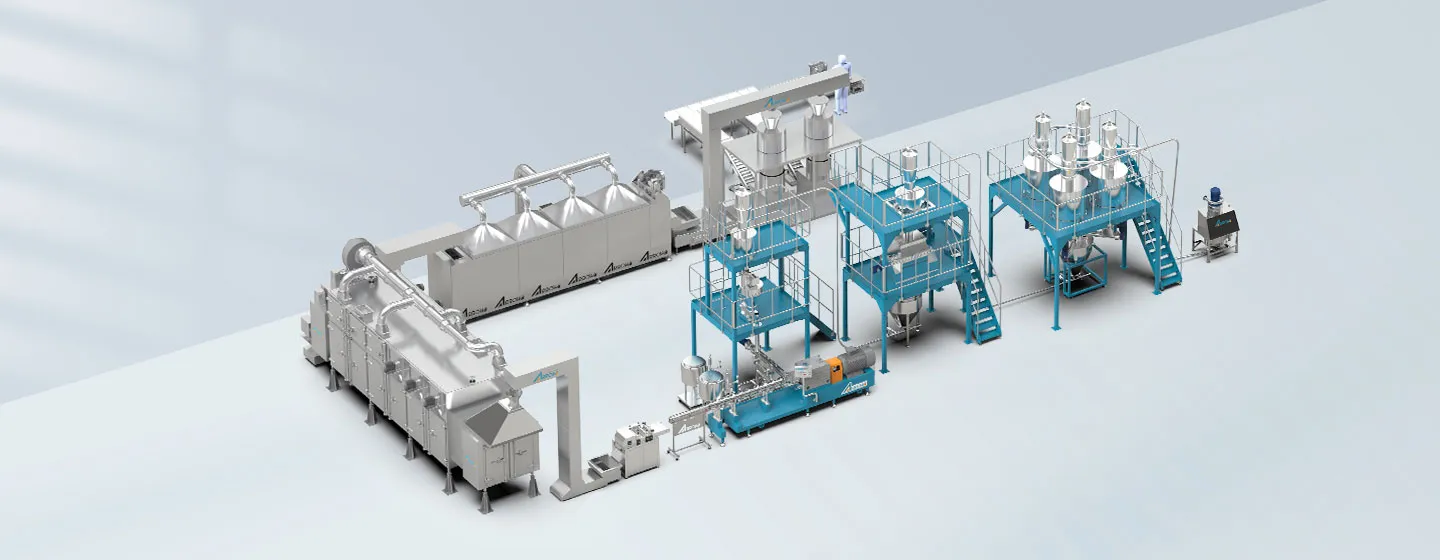

Using soybeans, legumes, and even microorganisms as raw materials, we have developed a series of plant-based meat solutions using protein as raw material. Through precise control of raw material ratios and process adjustments during the extrusion process, we can achieve changes in product shape, formula, texture, flavor, and optimize production processes. We also use intelligent centralized control and implement MES system integration. We provide production process monitoring, help factories achieve lean production, effectively help enterprises realize intelligent manufacturing, improve production efficiency, and realize production processization, standardization, and digitalization.

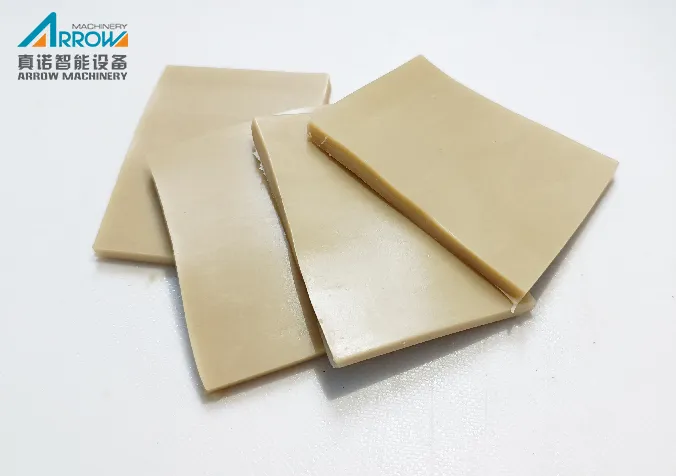

Finished Product Display

Production Process

Plant Protein

-

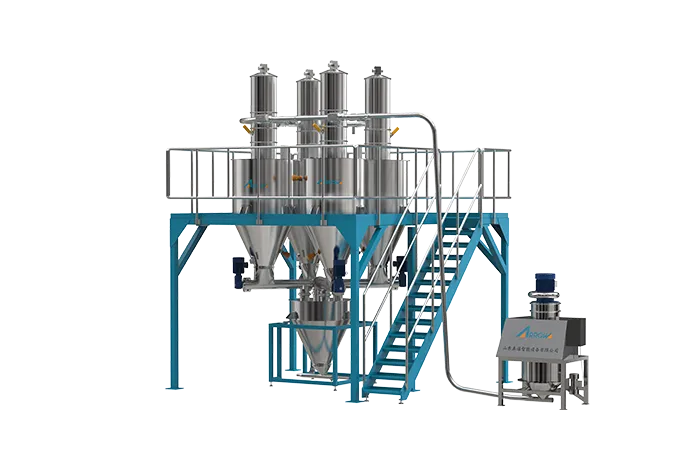

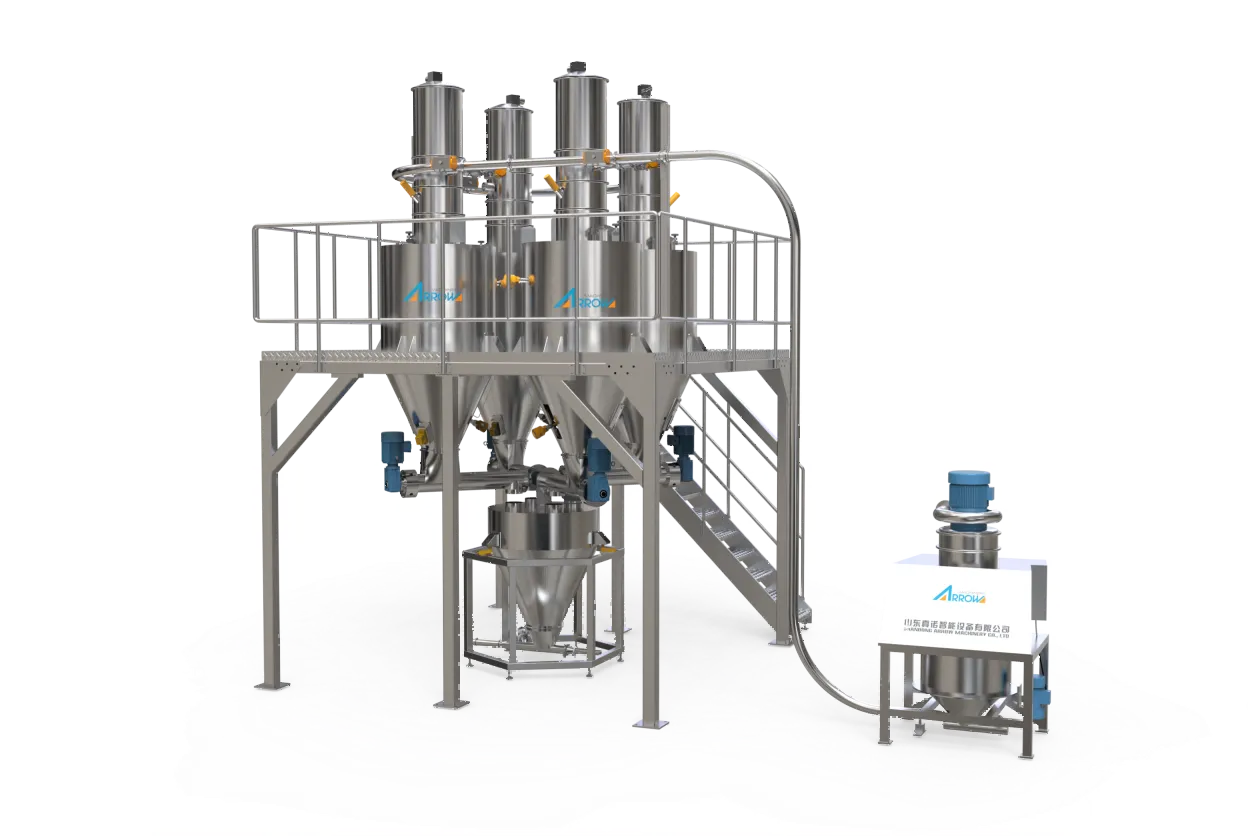

Batching

01

Batching

01Learn MoreIt can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02Learn MoreAdopting a double-layer rotor design, the mixing time is short, the uniformity is high, and the raw materials can be fully mixed. At the same time, a large section return air duct is equipped to reduce dust pollution.

-

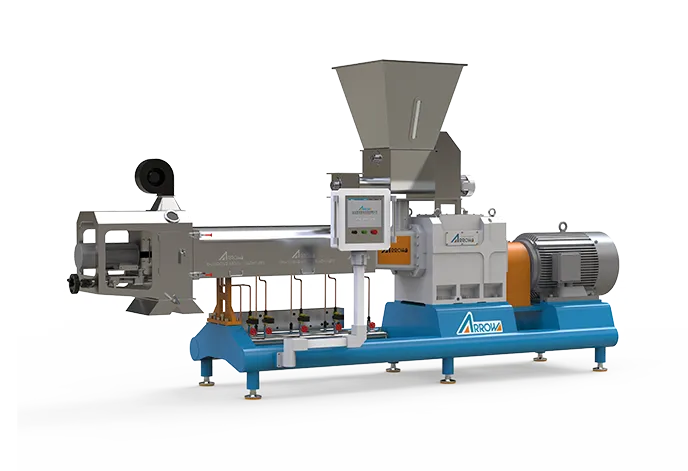

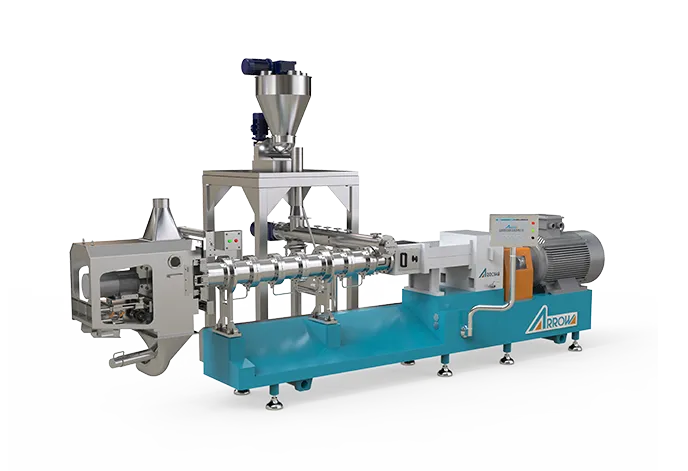

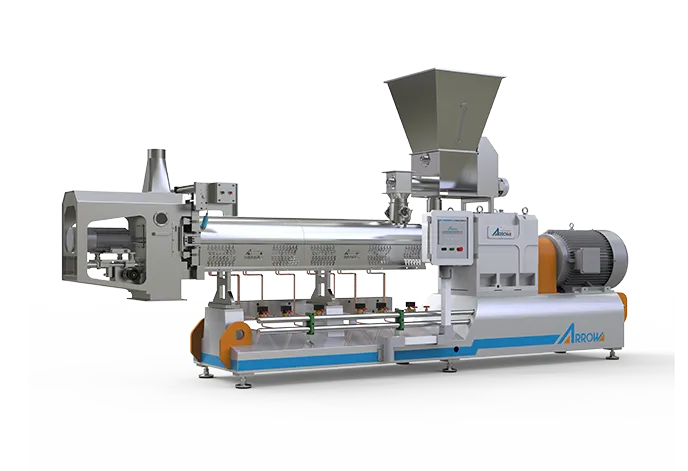

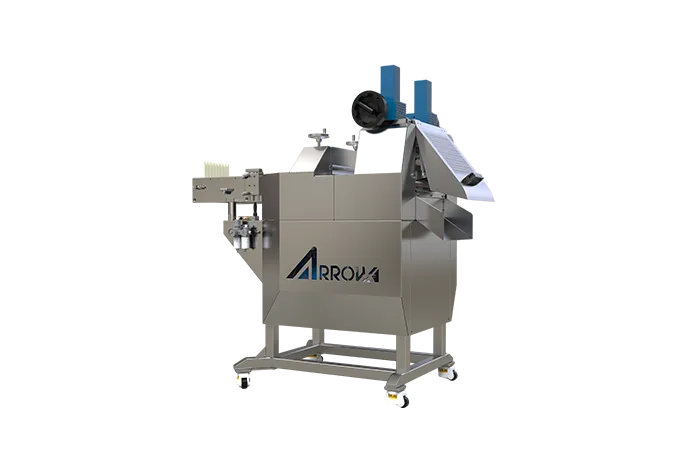

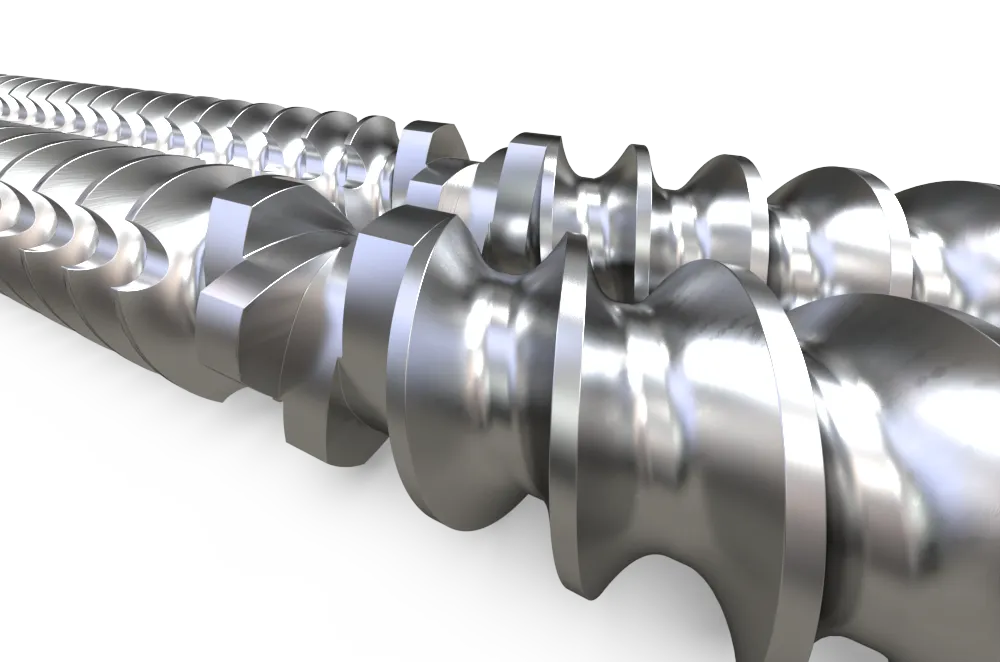

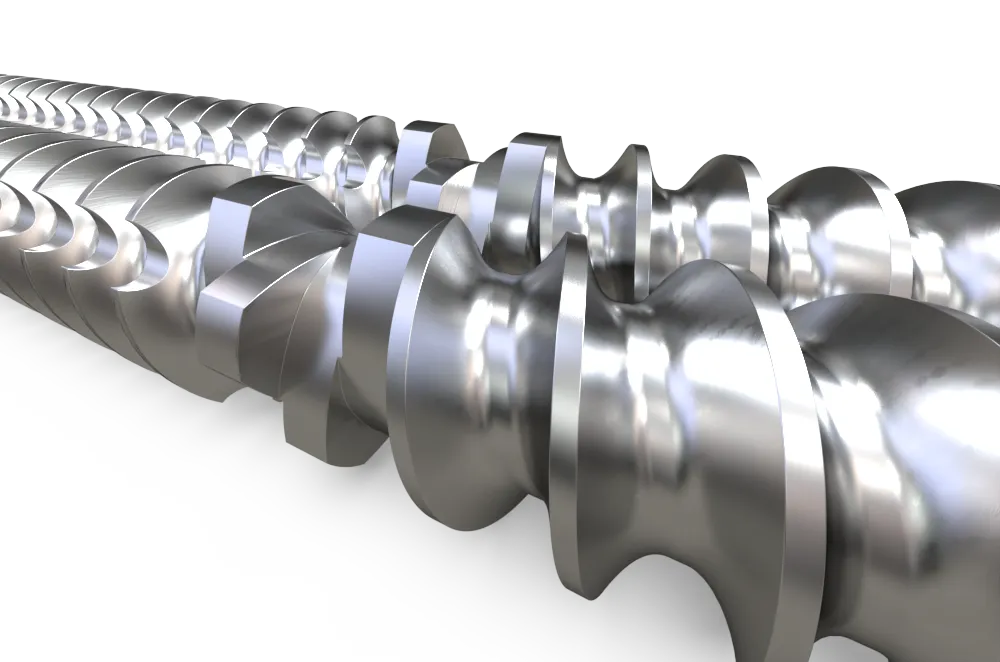

Extrusion

03

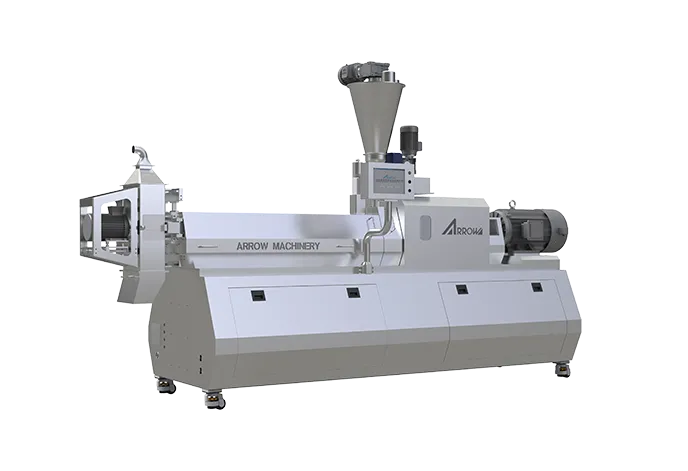

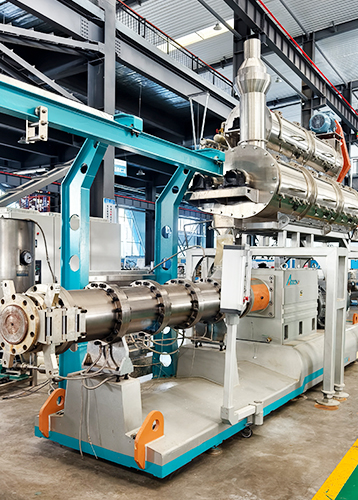

Extrusion

03Learn MoreThrough the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

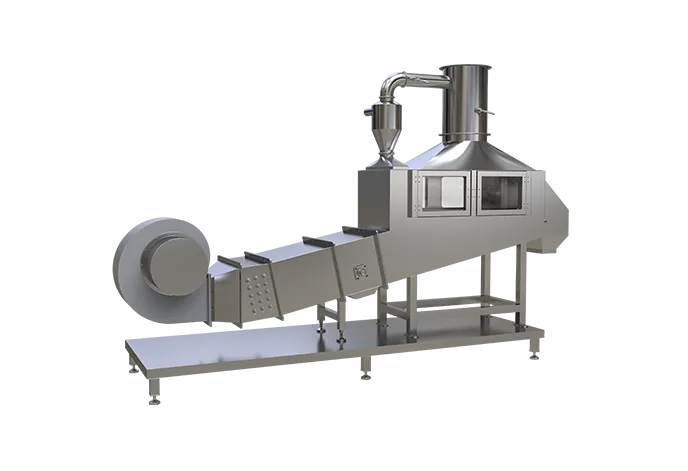

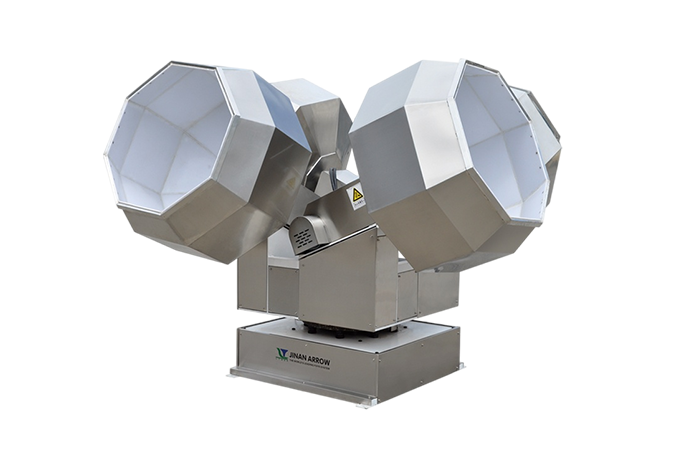

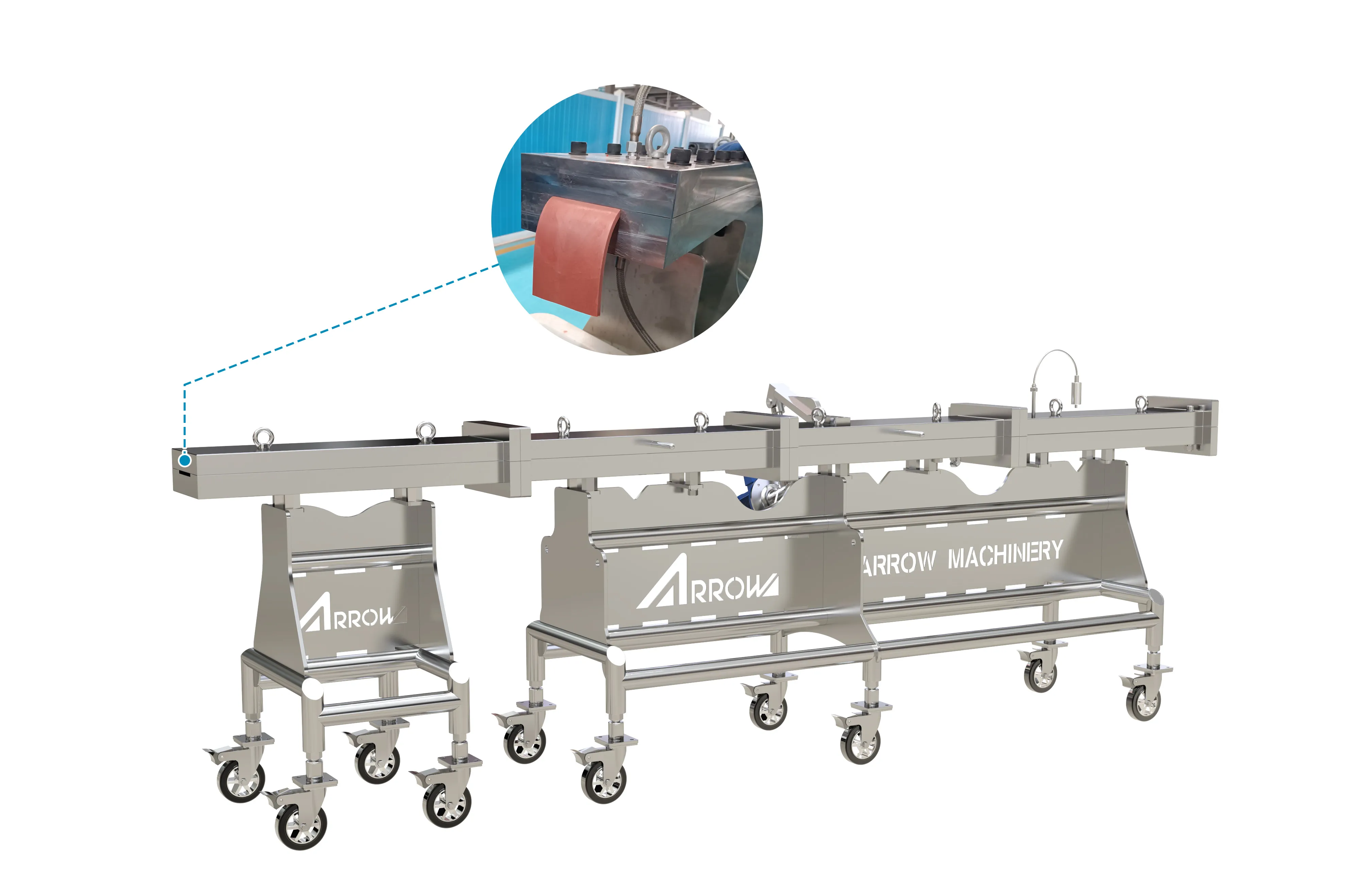

Forming

04

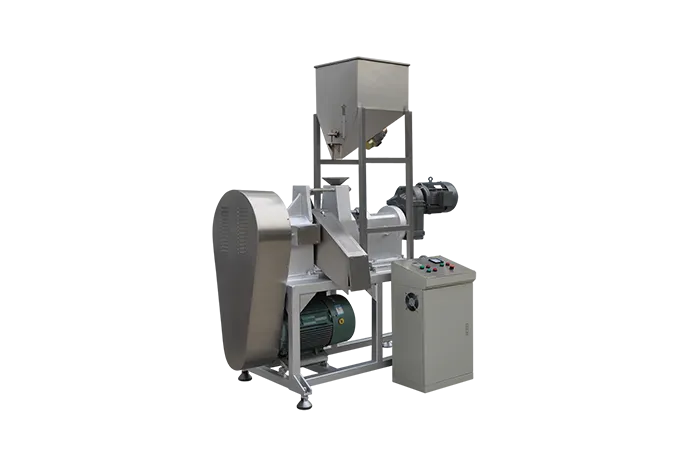

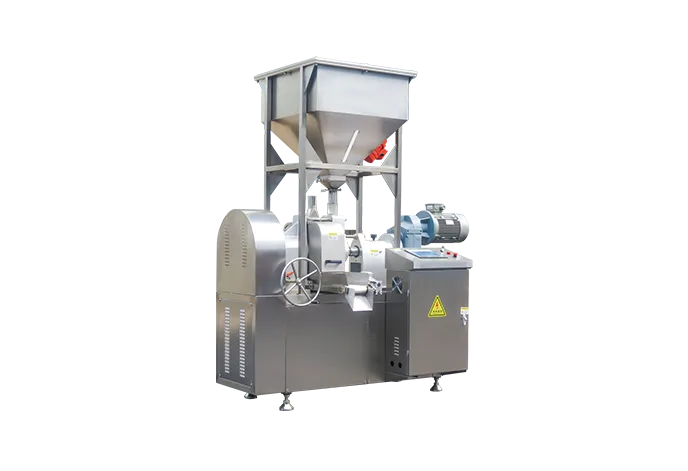

Forming

04By changing the mold, forming machine and cutting machine to change the shape of the product, the raw materials are accurately converted into products of the required shape.

-

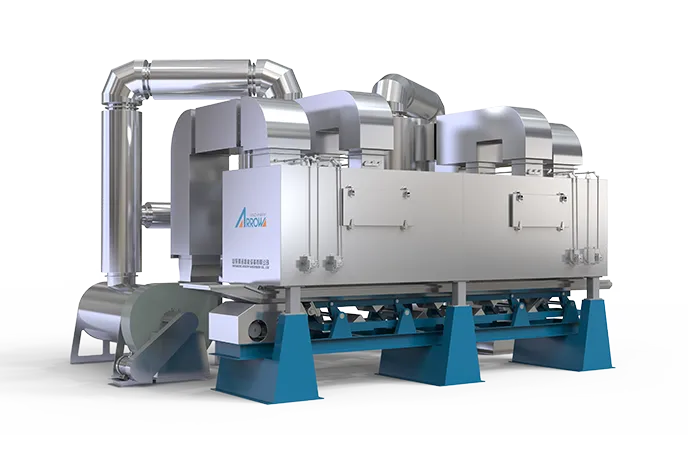

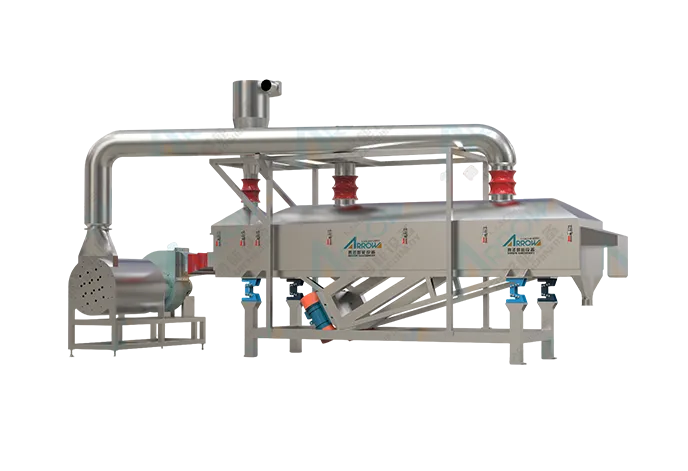

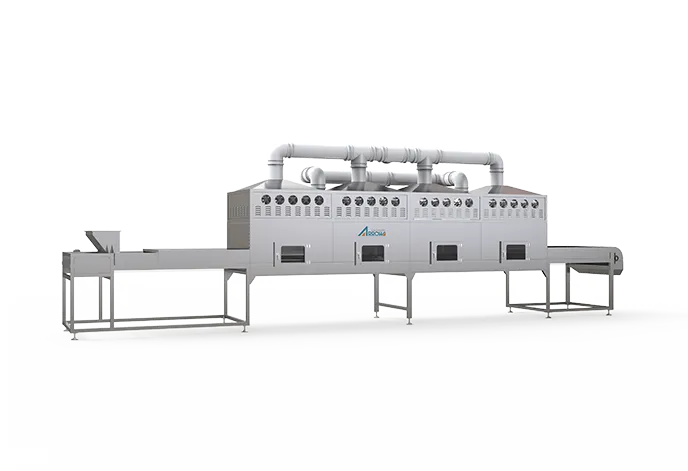

Drying

05

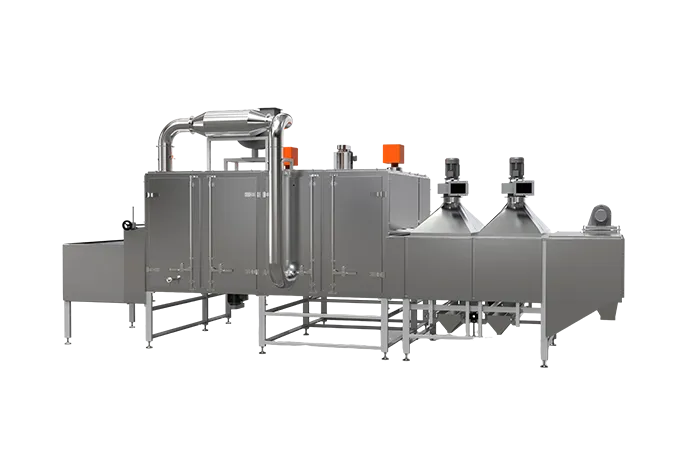

Drying

05The dryer features a forced hot air circulation system to improve thermal processing efficiency. The heat source can be a variety of heat media, including electricity, natural gas, fuel oil, and steam. The control system uses a PLC module for more precise temperature control.

-

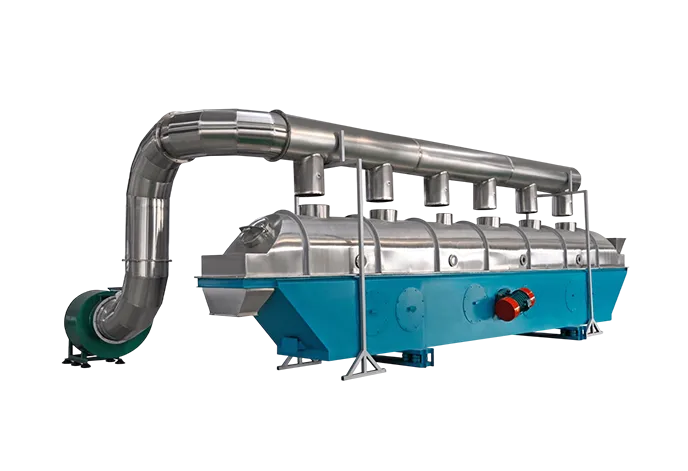

Cooling

06

Cooling

06The product is quickly and evenly cooled and ventilated and dried through cooling equipment to quickly fix its puffed structure and remove excess heat, maintaining the product's crispness and taste and preventing deterioration.

Textured Soya Protein

Plant Protein

-

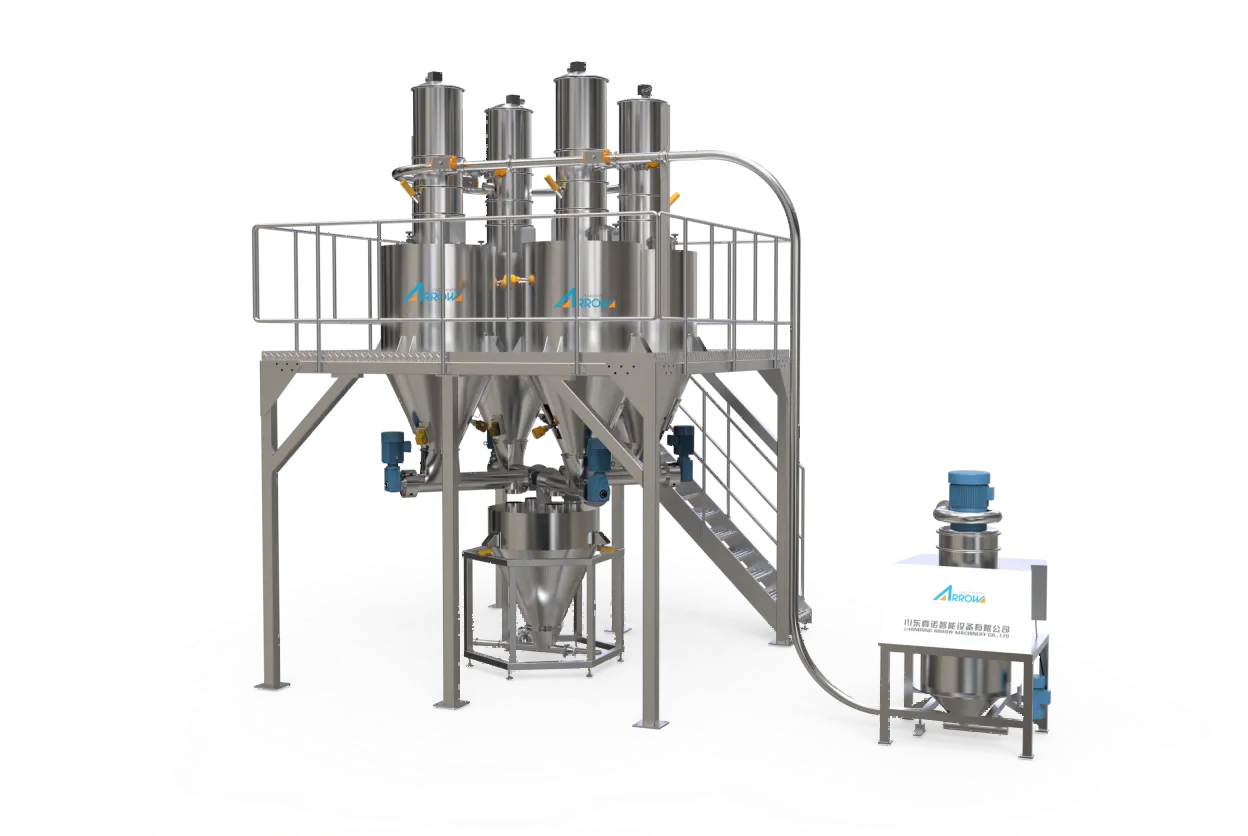

Batching

01

Batching

01It can realize automatic feeding and batching of various materials and adopts microcomputer control to meet your precision and accuracy requirements.

-

Mixing

02

Mixing

02The double-layer rotor design has a short mixing time and high uniformity, which can fully mix the raw materials. It is also equipped with a large-section return air duct to reduce dust pollution.

-

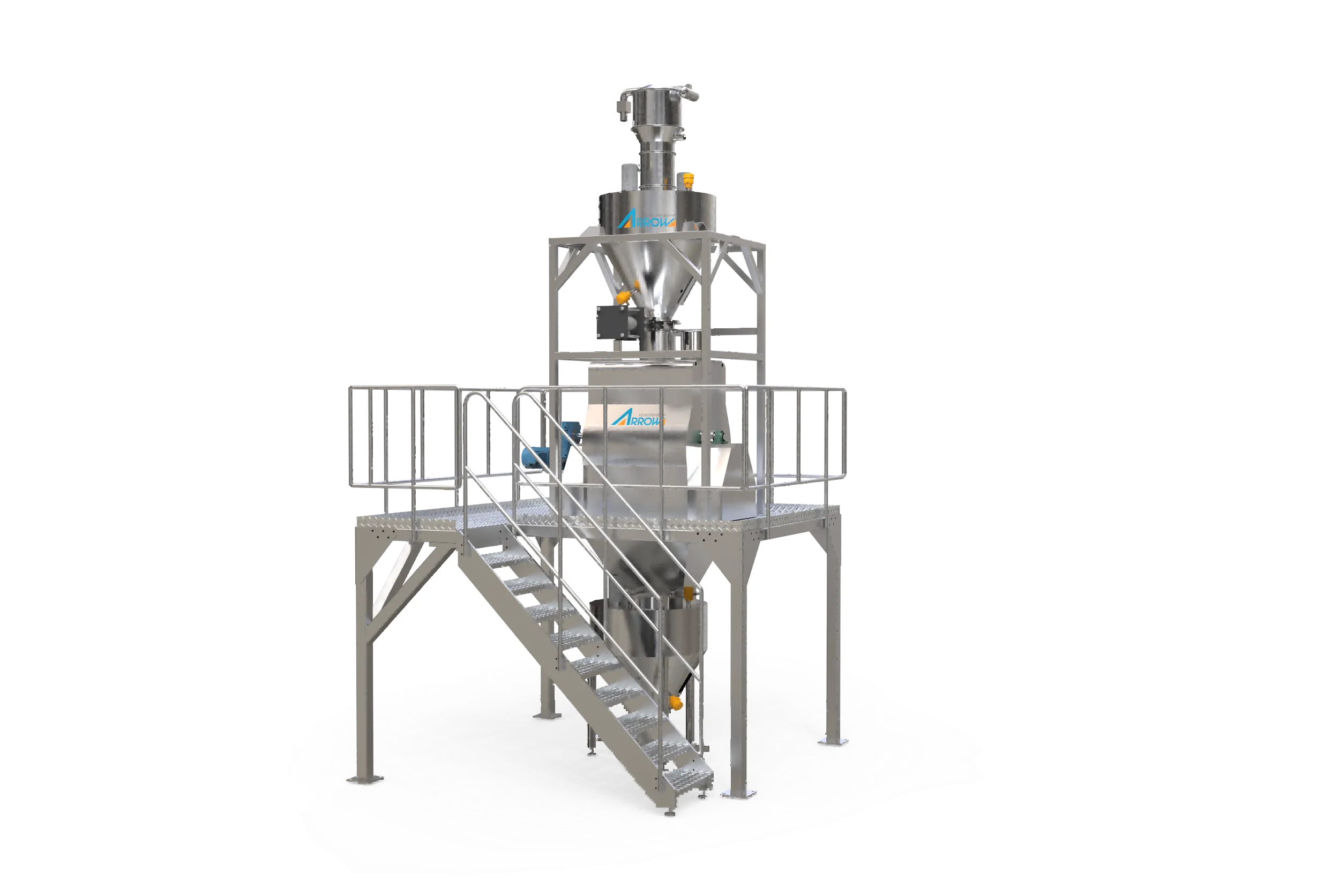

Extrusion

03

Extrusion

03Learn MoreThrough the rotation and extrusion of the twin-screw extruder screw, the raw materials undergo shearing, mixing, and aging processes under high temperature and high pressure, and are then molded into the desired shape and size through a mold.

-

Forming

04

Forming

04A special cooling sleeve device is used to shape and cool the plant protein, and the product texture can imitate different structures such as chicken, fish, and beef.

High Humidity Protein

Our Industry Advantages

-

Over 30 Years Of Industry Experience

We have over 30 years of experience in the manufacturing of extruded foods and are familiar with global development trends. Through close cooperation with you, we provide you with a one-stop solution that suits you, including full process design, workshop layout design, and workshop construction guidance.

-

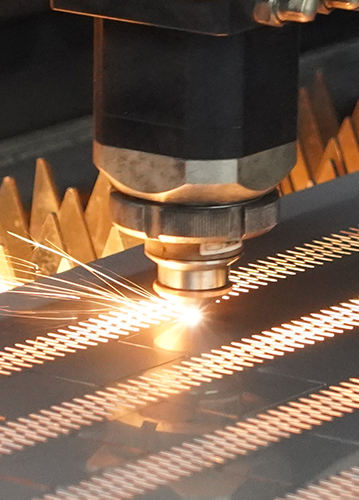

Leading the production frontier

We focus on creating intelligent, efficient, long-lasting, and low-energy fully automated production solutions to ensure stable system operation and lead the industry's technological forefront. Every process strictly follows food safety standards to safeguard your production.

-

Product Innovation

Our team of food technologists and engineers work closely together to keep pace with market trends and understand evolving tastes. We continuously innovate equipment and formulations to create tailored extruded food solutions that meet future market demands and help us pioneer new trends in the industry.

-

Global quality service

Our machinery and engineering services are available in over 110 countries and regions. Regardless of your location, you can expect responsive, attentive service. Our dedicated team is always on hand to resolve production issues, optimize your facility performance, and ensure a smooth and worry-free production journey.

Comprehensive Customized Engineering Solutions

We have established a comprehensive customized engineering solution system and clearly set up a medium - to long-term strategic blueprint, aiming to implement standardized management throughout the entire process of product design and development, efficient procurement, lean manufacturing, precise sales, and excellent service, ensuring that every aspect of the product from concept to delivery meets the highest standards.

This system not only ensures comprehensive protection of the product realization process, but also weaves the entire process into a seamless value creation chain, where each link is a deep exploration and appreciation of value, ultimately bringing customers a value experience beyond expectations, creating growth space for employees, achieving win-win cooperation for suppliers, and actively giving back to society to build a harmonious value ecosystem.

Service Process

-

01

Inquiry

-

02

Design

-

03

Testing

-

04

Plan

-

05

Manufacturing

-

06

Logistics

-

07

Installation

-

08

Debug

-

09

Training

-

10

Turnkey Project

-

11

Service