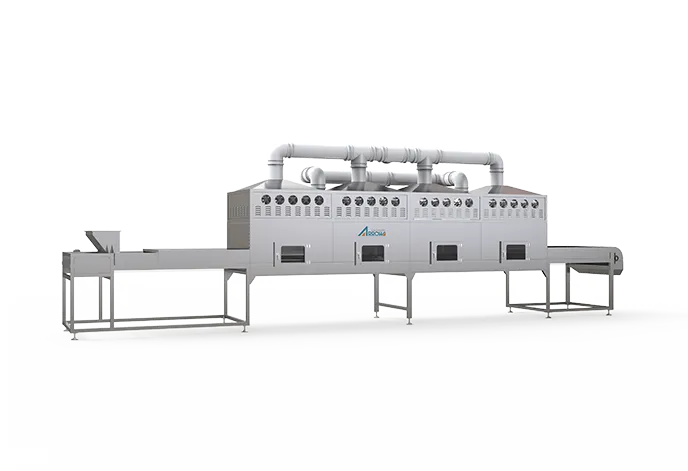

Microwave Applications in Food Sterilization

2024-12-02Microwave sterilization technology is a method that uses the thermal and non-thermal effects of microwaves to eliminate or inhibit microorganisms in food, medicine, packaging materials and other items.

Principle:

Microwave sterilization in microwave sterilization equipment utilizes the combined effects of electromagnetic field thermal and biological effects. The thermal effect of microwaves on bacteria denatures proteins, depriving them of nutrients and survival, leading to their death and sterilization, thus achieving the goal of food sterilization and preservation. The biological effect of microwaves on bacteria is that the microwave electric field alters the potential distribution across the bacterial cell membrane, affecting the electron and ion concentrations around the cell membrane and altering the membrane's permeability, resulting in malnutrition and disruption of normal bacterial metabolism.

Application:

In general, molds, yeasts, and common bacteria can be killed by heating to 70-80 ℃. If microwave is used for 1 minute, sterilization can be achieved. For fungal spores, such as those of Penicillium, they need to undergo 20 minutes of routine sterilization at 68-71 ℃ to disappear, while using microwave at 68-71 ℃ for 2 minutes is more convenient to obtain satisfactory results. If microwave is used to sterilize, prevent mold and preserve "mooncakes", good results have been achieved, and imported "preservatives" are no longer needed. Good results have been achieved in drying and sterilizing soybean powder, chicken essence, and sweet potatoes.

Advantage:

- Microwave sterilization technology has a wide range of applications and is suitable for various types of products, such as dried fruits, seasonings, tea, medicinal materials, etc. It can also effectively sterilize materials that are difficult to handle by traditional methods.

- Traditional heating methods often transfer heat from the outside to the inside, while microwave heating is carried out simultaneously inside and outside, making the temperature distribution inside the material more uniform and avoiding the problem of surface burning and internal failure to reach sterilization temperature.

- Maintaining nutrition and flavor, due to the short processing time, can reduce the loss of nutrients in food to a certain extent, and help preserve the original color, aroma, and taste of the food.

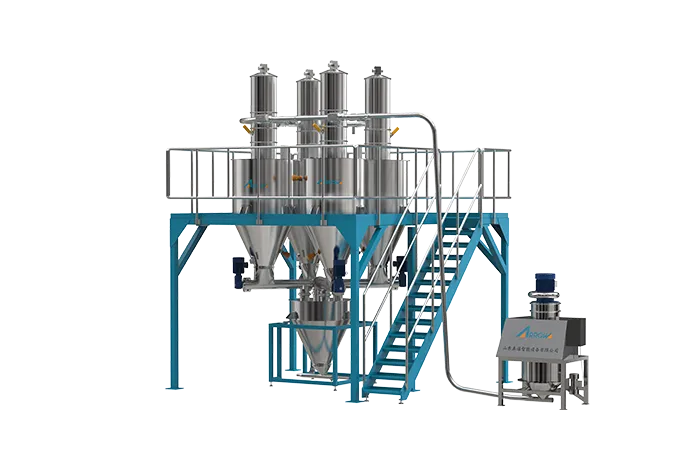

- Easy to control microwave sterilization process, temperature and time can be precisely controlled by adjusting power, with simple operation and high degree of automation, suitable for large-scale industrial production.

- Compared to traditional steam or hot water sterilization methods, microwave sterilization has lower energy consumption, reduces energy consumption, and also lowers wastewater and exhaust emissions, which is beneficial for environmental protection.

Points to note:

When sterilizing packaged food, if plastic material is used, it is not recommended to use polyethylene (PE) as it is prone to softening. Polypropylene (PP), ABS, polycarbonate (PC), polyester (PET), and nylon can all be used in the microwave; If glass bottles are used, quartz glass, silica glass, and soda lime glass are preferred. Tempered glass and ordinary glass are not recommended to be placed in the microwave as they may explode; If the paper material is made of wood cellulose, short-term heating is not a problem. The material is relatively dry, and the microwave field is uneven, which may cause it to stick or catch fire. Attention should be paid when using it.

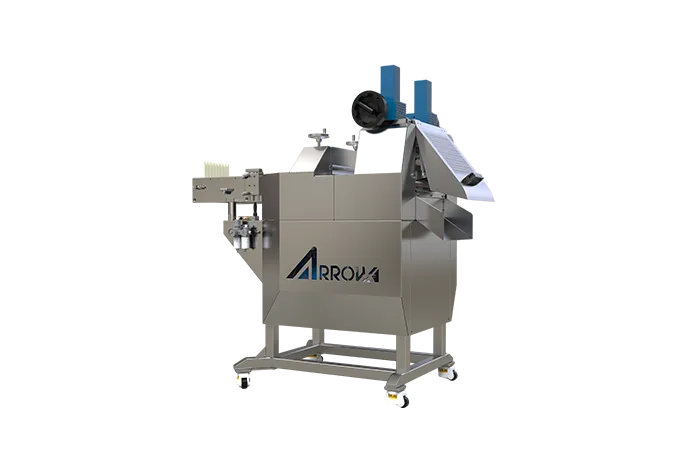

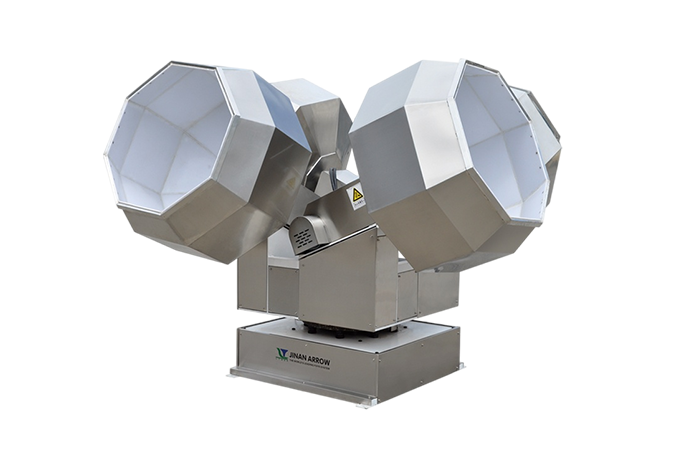

Our factory has been engaged in the microwave industry for more than 20 years, with hundreds of cooperative customers. We have rich experience in microwave food sterilization applications. If you need it, please leave a message for consultation and negotiation of cooperation!